Is CNC machining better than conventional?

WHAT ARE CNC MACHINES?

Computer-numerical control machining is a process used primarily by manufacturers to produce machined parts, products, items. CNC machines are what accomplish the process.

A CNC machine is a machine that utilizes Computer Numerical Control over machine tools like lathes, routers, grinders or mills. Computer Numerical Control is different typical PCs in the type of software used to control the machine, which is specially customized and programmed with G-Code — a specific CNC machine language that allows precise control of features like speed, location, coordination and feed rate.

Images source: Internet

IS CNC MACHINING BETTER THAN CONVENTIONAL?

CNC machining and conventional machining aim to achieve the same end, and both start with a raw chunk of metal or plastic and shape it into a part. The most basic difference between the two is the automation of CNC versus the manual nature of conventional. Speed, production rate, and accuracy are some of the main advantages of CNC machining over conventional machining.

With CNC, a skilled employee programs software to cut the part. With conventional, a skilled employee takes all the steps to setup and operate the machine. In the manual situation, a highly skilled operator must also set the gears, whereas CNC machining does not use gears.

Conventional typically costs less and is used for small-quantity projects. CNC machining is normally used for high quantities and is not as cost-effective for smaller ones.

Imagine a hypothetical part, for example. A component needs concave and convex arcs, imperial and metric threads and two tapers of differing degrees. An automated CNC machine would use three tools to cut the part, while the conventional machine would require five tools and no doubt more time.

Among the first things to happen with CNC machining is the use of computer-aided design (CAD) software to produce a two- or three-dimensional model of the final component. The prototype image of that component is then fed into the software, which operates through the computer to command the machining tools to produce items identical to the model.

Once the computer has loaded in a new image for CNC machining, it can pull that model up again and again to produce more of what it is, which is another of the CNC machine advantages. The technology is designed to achieve machining accuracy within 0.0001.

Images source: Internet

WHAT ARE THE CNC MACHINE ADVANTAGES?

Anyone responsible for planning the manufacturing of metal parts and components would want to know what benefits they gain using CNC machining. While the type of businesses and products differ, the CNC advantages are clear.

ADVANTAGES OF CNC MACHINING

Precision Components: The digital template and autonomous machining of CNC practically eliminate human error and achieve accuracy within 1/1000th.

High Production and Scalability: Once the design parameters and specifications have been entered into a CNC machine, it consistently executes huge quantities and affords flexible scalability.

More Capability: When used in tandem with advanced design software, CNC machines create outputs that cannot be replicated by manual machines. Even the most gifted engineers can’t do with conventional machines what advanced software can do with CNC machines. These machines can produce any size, shape or texture needed.

Uniform Product: When you choose the advantages of CNC machines over conventional machines, your CNC outputs match exactly. Even the most talented engineers on a conventional machine will produce components that vary slightly. With CNC machines, each part is a perfect match to the prototype’s exact specifications.

.jpg)

Lower Costs: The collective result of high speed, efficiency, specialization, precision and most of all, fewer labor hours, all add up to a better bottom line for your business. The lower costs, in turn, can be used to create a competitive advantage and business re-investment. Saving money or making more money is one of the popular benefits of CNC machining.

Better Safety: Along with an expedient production process and consistent pieces comes a safer environment. While there are operators involved in operating CNC machines, it’s at a distance the sharp tools, whereas the operators of conventional-manual lathes, drills, punches and other tools come into direct contact with the implement.

Versatility: CNC machining itself creates virtually any component you can imagine. Some of the models include special features and accessories that further expedite and simplify the production process, for example touch screens and automated tool changers.

.jpg)

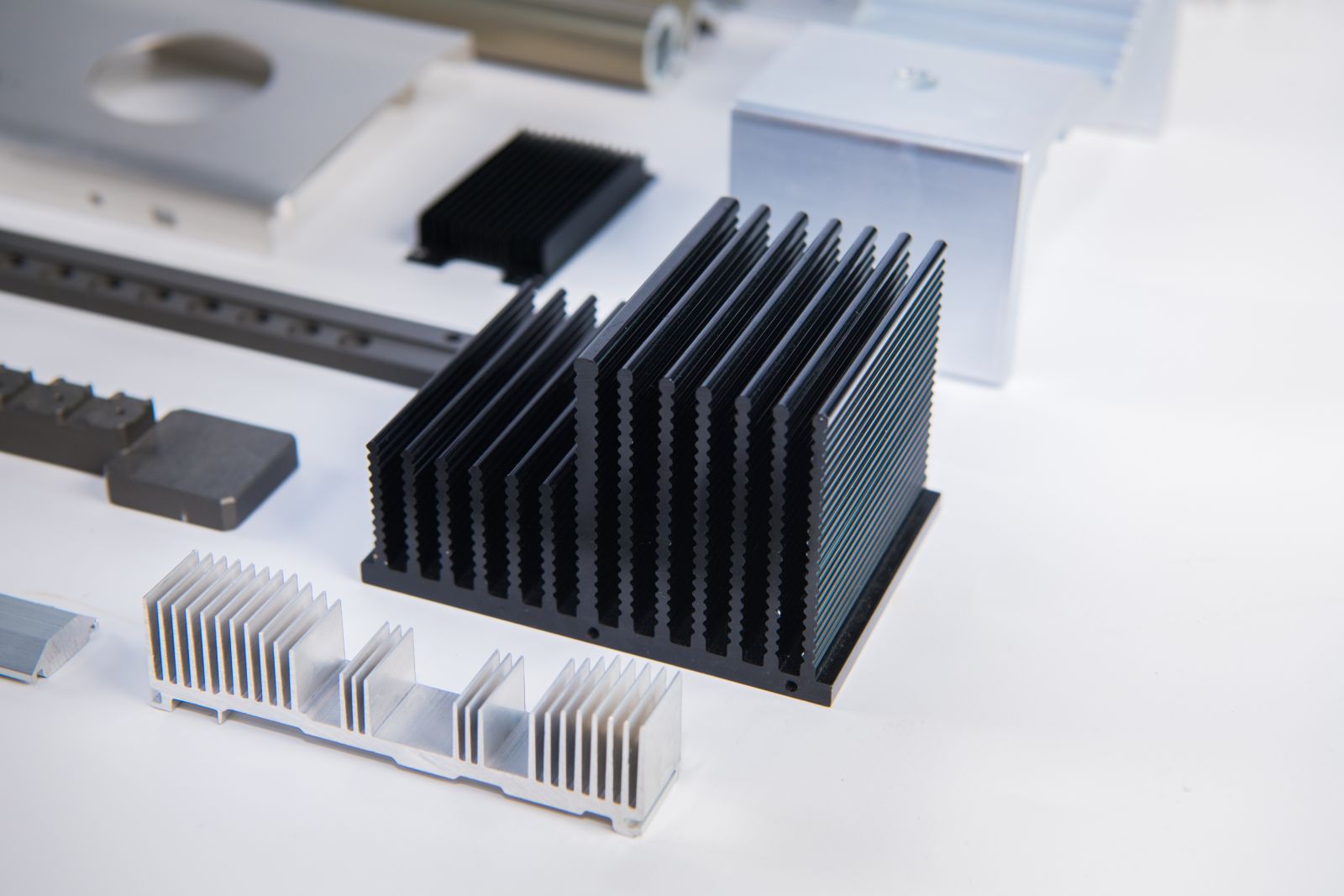

With the purpose of providing customers with high precision mechanical details and finished products, KIMSEN is equipped with modern machining system allows the production of parts with high accuracy that meets the diverse requirements of customers. Precision Machining Services include: CNC milling, CNC cutting, drilling, punching, bending, etc. Modern machineries are imported the leading equipment suppliers in the field, in order to ensure the high accuracy of the products.

At KIMSEN, we have multi-axis CNC milling machines in our factory (fully stacked with more manufacturing equipment). We also have expert staff skilled in the engineering software used to run these machines.

>> Check out our Precision Machining Products

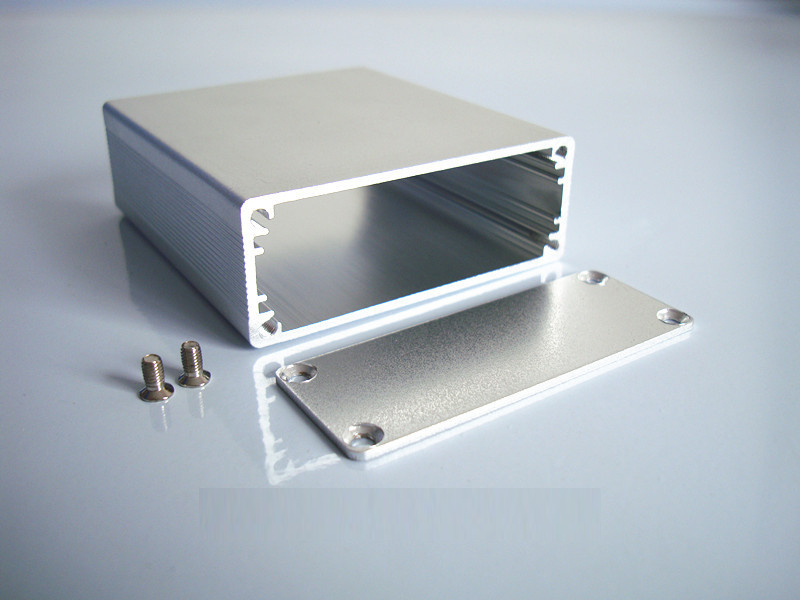

KIMSEN is proud to bring high quality aluminum extrusion, components & modules which meet international standards.

For specific advice, please contact Hotline +84 93 867 6005 or email info@kimsen.vn

KIMSEN INDUSTRIAL CORPORATION

Head Office & Factory: Yen Phong Industrial Park, Yen Phong Dist., Bac Ninh Pro., Vietnam

Hanoi Office: 14th floor, TTC Tower, No. 19 Duy Tan Str., Cau Giay Dist., Hanoi, Vietnam

Hotline: +84 93 867 6005

Email: info@kimsen.vn

*Reference: https://www.fairlawntool.com/blog/advantages-cnc-machines/

Chia sẻ:

Chia sẻ: