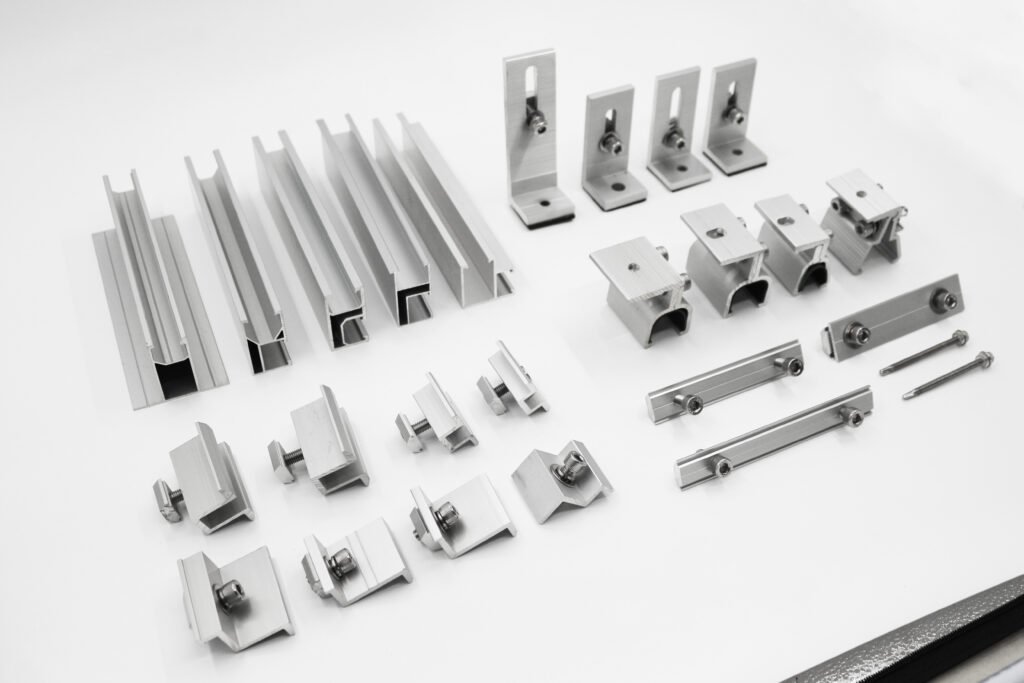

Top Aluminum Alloy for Solar Mounting Systems

Understanding Aluminum Alloy for Solar Mounting

Why aluminum alloy for solar mounting is ideal for PV systems

Aluminum has become the gold standard for solar racking systems. But not all alloys perform equally under pressure—literally. The right aluminum alloy for solar mounting must combine mechanical durability with light weight, high corrosion resistance, and ease of fabrication. That’s where the 6000-series shines.

Key performance factors for aluminum solar racking materials

The solar industry relies on aluminum for three reasons:

- Corrosion resistance: Even in humid, coastal, or snow-heavy zones, aluminum holds up

- Weight-to-strength ratio: It reduces load without compromising support

- Recyclability: Solar is a green industry—aluminum is a perfect fit

In systems exposed to wind uplift and snow loads, the alloy strength PV considerations are critical. Choosing between 6005-T5, 6063, and 6061 alloys can make or break your racking’s performance and longevity.

Best Aluminum Alloy for Solar Mounting Structures

6005-T5 aluminum alloy for solar mounting systems

Currently one of the most widely used alloys in solar racking, 6005-T5 offers a strong blend of tensile strength, good corrosion resistance, and excellent extrudability. It’s particularly useful in structural profiles that must carry weight—like rails, L-feet, and post brackets.

- Yield Strength: ~190 MPa

- Good machinability

- Commonly anodized or powder coated for extra protection

6063 solar alloy for anodized, architectural PV frames

Though slightly lower in strength than 6005-T5, 6063 solar alloy provides exceptional surface finish and is favored in projects where aesthetics and anodizing are key. Think of carports, facade-integrated solar, or building-integrated PV (BIPV).

- Yield Strength: ~145 MPa

- Highly resistant to corrosion

- Ideal for anodizing

Using 6061-T6 aluminum alloy in high-load solar racking

Used where structural loading is intense—like elevated solar racking in windy zones—6061-T6 offers the highest strength of the group, but with slightly reduced formability and extrudability.

- Yield Strength: ~240 MPa

- Heat-treatable

- Weldable with proper process controls

Comparing 6082 and 6060 alloys for solar mounting brackets

6082 is gaining traction in European installations for its higher tensile strength and strong anti-corrosion profile, while 6060 remains a niche option where slim-profile extrusions are required.

- Both suitable for anodizing

- 6082 delivers strength close to 6061 but with slightly better surface finish

Alloy Strength PV: Mechanical Performance & Corrosion Resistance

Evaluating yield strength and load capacity in solar mounting alloys

When designing solar mounting systems, engineers must consider alloy strength PV values like yield and tensile strength. Below is a quick comparison (July 2025 average values):

| Alloy | Yield Strength (MPa) | Surface Finish | Common Use |

|---|---|---|---|

| 6005-T5 | 190 | Good | Structural racking, rails |

| 6063 | 145 | Excellent | Carports, building facades |

| 6061-T6 | 240 | Moderate | Heavy-duty mounting, beams |

| 6082 | 240 | Good | Wind-prone sites, utility use |

| 6060 | 110 | Excellent | Lightweight framing |

Corrosion resistance of aluminum alloys in outdoor PV installations

For U.S. buyers dealing with wind zone requirements (ASCE 7-16) or EU clients in snowy northern climates, choosing the right alloy based on yield strength and extrudability is key to meeting code and ensuring system longevity.

Extruding and Finishing Aluminum Alloy for Solar Mounting in Vietnam

Extrudability and surface treatment for 6005-T5 and 6063 solar alloy

Vietnam’s aluminum extrusion sector has matured significantly. With tariff exemptions under EVFTA (for EU) and reduced trade tension from recent US-Vietnam agreements (amid 2025 tariff reevaluations), sourcing solar racking components from Vietnam is both smart and scalable.

Powder coating and anodizing finishes for PV-grade aluminum profiles

KIMSEN Industrial Corporation stands out as a leading manufacturer for solar mounting aluminum in Vietnam. Key offerings:

- ISO 9001:2015 certified extrusion lines

- Dedicated surface finishing lines for anodizing and powder coating

- Tight-tolerance CNC processing and assembly

- Export packaging per US & EU standards

Applications of Aluminum Alloy in Solar Mounting Systems

Rooftop PV systems using 6005-T5 and 6063 solar alloy

Use 6005-T5 or 6063 when form and finish matter, especially for residential or small-scale C&I installations. Profiles must be lightweight and resistant to salt (coastal rooftops) or acidic rain.

Ground-mounted and utility-scale PV frames with high alloy strength

6061-T6 and 6082 work best here. These alloys resist sag under longer spans and can be welded or bolted easily. Ideal for:

- Agricultural solar

- Utility-scale PV farms

- Carports with wind shear risk

Lifecycle Benefits of Aluminum Alloy for Solar Mounting

Sustainable sourcing and recycling of solar mounting aluminum

One overlooked benefit of choosing the right aluminum alloy for solar mounting is its end-of-life recyclability. All 6000-series alloys are 100% recyclable without loss of performance. This:

- Reduces long-term material waste

- Supports LEED or BREEAM certification

- Lowers embodied carbon footprint

Lifecycle carbon savings with recycled aluminum for PV systems

KIMSEN’s extrusion process also uses up to 20% recycled billet content (as of Q2 2025), reducing CO₂ per kg of aluminum by nearly 15% compared to fully primary sources.

Why Source Aluminum Alloy for Solar Mounting from Vietnam

KIMSEN Industrial Corporation – Vietnam’s top solar alloy supplier

When quality, price, and logistics matter, KIMSEN Industrial Corporation is a proven partner. Their end-to-end extrusion, finishing, and machining capabilities simplify the supply process while ensuring you meet every project spec—on time and on budget.

2025 trade and tariff advantages in solar mounting aluminum sourcing

With unpredictable supply chains due to the lingering impact of the Ukraine-Russia war, and elevated costs from 2025 US-China trade tariffs, Vietnam is emerging as a secure and cost-effective sourcing hub.

Design Tips: Selecting the Right Aluminum Alloy for PV Mounting

Matching aluminum alloy strength to wind and snow load zones

Make sure the alloy’s strength and form factor matches the environmental load.

Choosing alloy and finish based on PV system type and location

Use anodized 6063 for urban designs; 6005-T5 or 6061-T6 for structural outdoor or utility sites.

Quick Takeaways: What to Remember About Solar Mounting Alloys

- 6005-T5 is the most used aluminum alloy for solar mounting systems due to strength and machinability

- 6063 solar alloy offers better surface finish for architectural or aesthetic solar builds

- 6061-T6 and 6082 provide high load-bearing support for utility-scale or wind-prone areas

- Vietnam offers cost-effective extrusion and finishing, especially through KIMSEN Industrial Corporation

- Alloys can be anodized or powder coated to boost corrosion resistance and enhance durability

- 6000-series aluminum is recyclable, aligning with sustainability goals for solar

Conclusion: Choose the Right Aluminum Alloy for Solar Mounting

In 2025, solar project developers, EPC firms, and aluminum buyers across the US and EU are seeking optimal performance with minimal delays and waste. Selecting the right aluminum alloy for solar mounting—whether it’s 6005-T5 for its balance, 6063 for its finish, or 6061 for its strength—makes a measurable impact.

Ready to elevate your solar infrastructure? Reach out to KIMSEN for your custom alloy profile needs and get the support of a team that understands solar just as well as you do.

Chia sẻ:

Chia sẻ: