Aluminum Dominates In Industrial Uses

Aluminum possesses several unique properties that make it very versatile and sought after for everything building aircraft to making soda cans. The fact that this metal is recyclable means that it will probably become even more popular in all uses as time goes on and other resources become more limited.

Weight

Aluminum is an extremely light metal, but still very strong. It is roughly one third of the weight of steel and less than one fourth of the weight of lead. This makes it extremely useful for many applications, especially in the transportation industry. Aluminum plate suppliers are constantly filling orders for those who build airplanes, boats, cars and trucks, since the lighter relative weight (or density) of aluminum compared to steel allows these vehicles to go faster, be more fuel efficient, carry more payload, float and fly.

Ease of Manufacturing

Aluminum is a very versatile metal, which allows it to be manufactured into many different forms, such as aluminum plate, bars, sheets or extrude shapes. Aluminum is created in a variety of different alloys and each specific alloy offers different benefits to manufacturing. For instance, 6061 aluminum alloy or 6063 aluminum alloy, are good for machined parts, while alloys like ADC12 or A380 are more suitable for casting. In the hands of a skilled craftsman with the proper precision equipment, aluminum can be cut or formed to just about any shape or size.

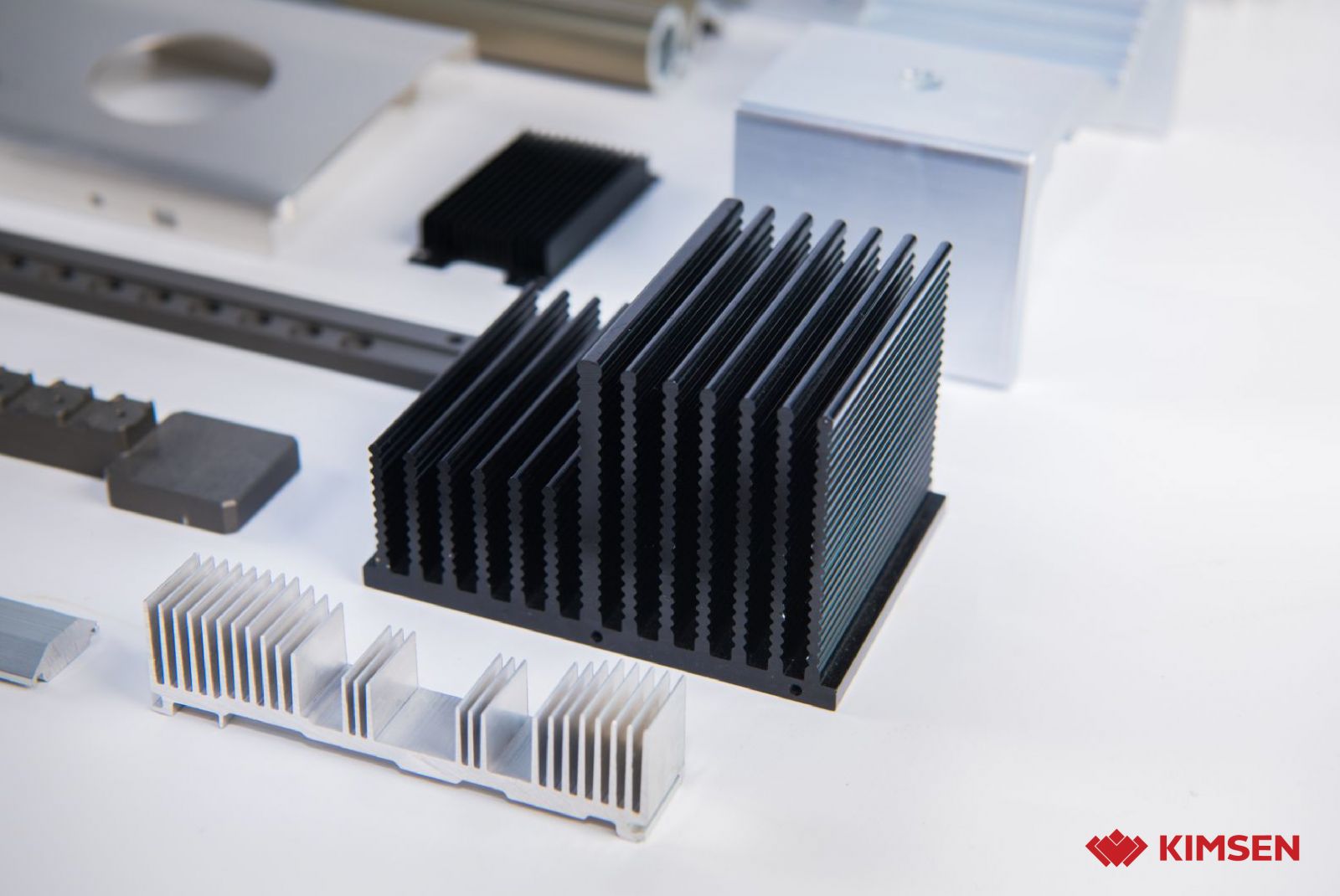

Conductivity

Aluminum conducts electricity very well. This property makes the metal very useful in the construction of electronics and circuits. It also has fairly good thermal conductivity, allowing it to transfer most of the heat or cold it receives evenly across its surface. This makes aluminum a very popular choice for heating, air conditioning equipment and is used as heatsinks in a variety of applications such as LED lights, electrical products, computer motherboards, etc.

Aluminum Heatsink

Home Features and Household Items

The use of aluminum just in a standard home is extensive. You can find this material present in window frames, cooking supplies, toasters, framework, door knobs, exercise equipment, golf clubs, and more.

Construction

Aluminum is used extensively in the construction industry due to its great versatility. The material can be cut, welded, and molded to produce a vast array of components and products. Construction applications also benefit due to its lightweight characteristic. This makes it a less expensive option than other metals. Aluminum in manufactured for various construction elements, such as windows and doors, railings, skylights, wiring, and shutters, among others.

Portable Displays and Framing

Extruded aluminum can be used in office furniture framing of cubicles and to create frameworks that are often used for displays at tradeshows or in retail shops.

Military and Defense

The defense industry also makes use of aluminum extrusions. The material is ideal for these applications due to its low weight and high strength. The applications including landing mats, military ships, all-terrain vehicles, and tent structures. Pretty much anything that will lighten the load for our troops to carry or transport is designed out of Aluminum.

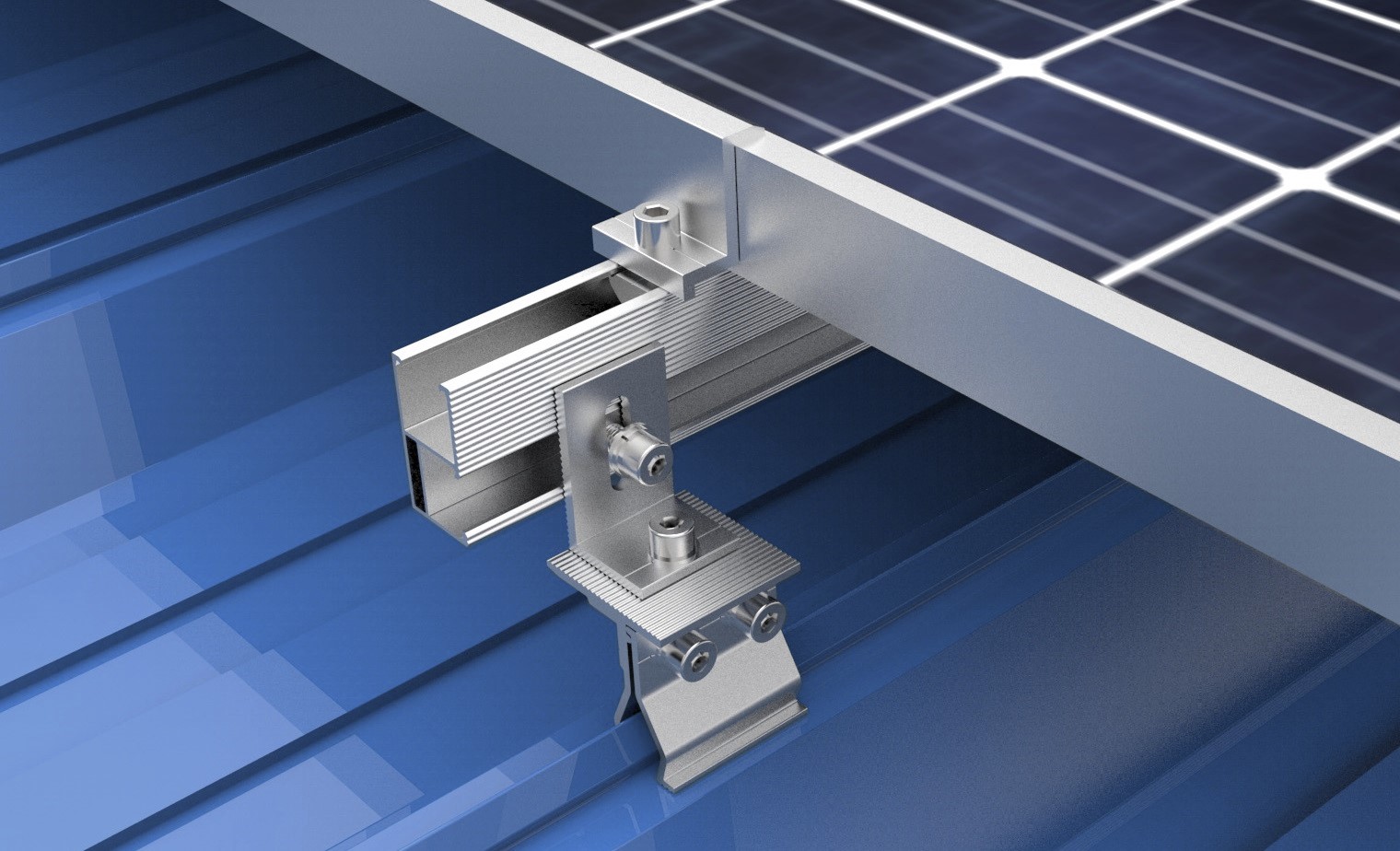

Energy

Copper has about one-half times the electrical conductivity of aluminum, making it better in many applications, but copper has its limitations in strength. This makes aluminum a great option for use in power system applications. Applications that involve the mounting of solar panels also make use of aluminum due to its low maintenance requirement and lightweight property. Some power structures benefit the use of aluminum due to its ability to support snow loads and high wind loads.

Solar Mounting & Racking Systems

Transportation

The transportation industry also benefits the manufacturing of aluminum. A primary benefit to this industry is its high strength-to-weight ratio, a great asset in the building of aircraft, cars, trains, and boats. Aluminum alloys can achieve sufficient strength for certain applications in the transportation sector that make it a highly advantageous option. Its strength helps it withstand loading and its low weight can increase the energy efficiency of operations in which it is used. This is the reason why a lot of car, truck and boat manufacturers are using aluminum extrusion for body frame and EV battery housing.

Aluminum Battery Housing

Packaging

The packaging industry also makes use of aluminum extensively. Aluminum is impermeable and it helps keep food clean and protected harmful environmental elements. Aluminum oxide is not a destructive element and aluminum itself is highly resistant to corrosion.

Aluminum does not contain or emit toxic elements and as a result does not alter the smell or taste of beverages or food it contains. This is an important benefit for food preparation and storage companies. Aluminum packaging is manufactured constantly in forms that include trays, cans, containers, bottle caps, foil, and more.

The manufacturing industry takes advantage of the various unique benefits afforded by aluminum to produce highly efficient and cost-effective products. Aluminum alloys continue to be created for specific applications. The benefits aluminum offers include its strength and lightweight characteristics, low cost, corrosion-resistance, electrical and thermal conductivity, along with its most important characteristic of recyclability, making it ideal for various industries and manufacturers.

Source: https://www.howardprecision.com/aluminum-dominates-the-manufacturing-industry/

Chia sẻ:

Chia sẻ: