Aluminum Anodizing Process

Images source: Internet

'What is Anodizing?

By definition, anodizing is "a process to electrolytically coat a metallic surface with a protective or decorative oxide". The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Coatings are 0.1 to 1.0 mil thick and are essentially transparent, although they may be colored.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through.

The Anodizing Process

The Anodizing process begins by immersing the work in a series of solutions where various operations are performed (described below). The solutions are held in open-top tanks and the work passes through each unit. The work usually consists of distinct items that are placed on special racks and carried through the process in batches.

Overhead cranes move the racks one tank to the next. The work is rinsed thoroughly after each operation to avoid contamination and interference in the next solution. A multiple-step process of anodizing includes:

- Cleaning: removes fabrication oils and buffing compounds by soaking the work in a water-based solution containing mild acids or alkalis along with dispersants and detergents.

- Pretreatment: used for decorative purposes to improve the appearance of a surface prior to the anodizing step. The most common pretreatments are etching, which imparts a satin, matte finish; and bright dip, which imparts a bright, shiny finish.

- Anodizing: produces the actual coating. Acting as the positive electrode, a direct current is passed through the item to be anodized while submerged in a bath of water and acid (sulfuric, chromic, phosphoric) used as the electrolyte. The water breaks down, liberating oxygen at the surface of the item, which then combines with the aluminum to form the coating - a transparent and microscopically porous layer of aluminum oxide. Thickness is determined by the level of electrical current and the length of time it is applied.

Images source: Internet

- Coloring: an option approached in either of two ways:

- Integral Color: imparts color to the coating as it is being formed in the anodizing bath, which has been modified for that purpose. This process produces various brass, bronze and black colors, while providing a more abrasion resistant coating than conventional anodizing. It is the most expensive process since it requires significantly more electrical power.

- Electrolytic Coloring (The two-step method): imparts color to the coating after it is formed and takes advantage of the fact that the freshly anodized coating is porous and therefore capable of absorbing colorants. After anodizing, the metal is immersed in a bath containing an inorganic metal salt. Current is applied which deposits the metal salt in the base of the pores. The resulting color is dependent on the metal used and the processing conditions (the range of colors can be expanded by over-dyeing the organic dyes, offering even more color versatility).

- Sealing: the pores on the surface of the finished pieces need to be closed before the anodized item is placed into service. If left unsealed, surfaces could have poor corrosion resistance, or absorb unwanted stains. Items that are not colored during or after anodizing retain the natural color of the metal.

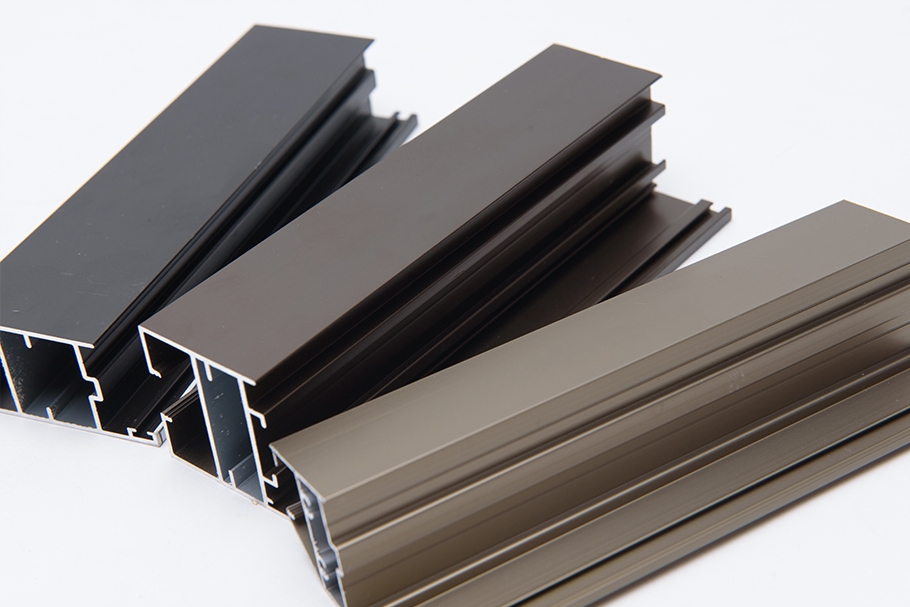

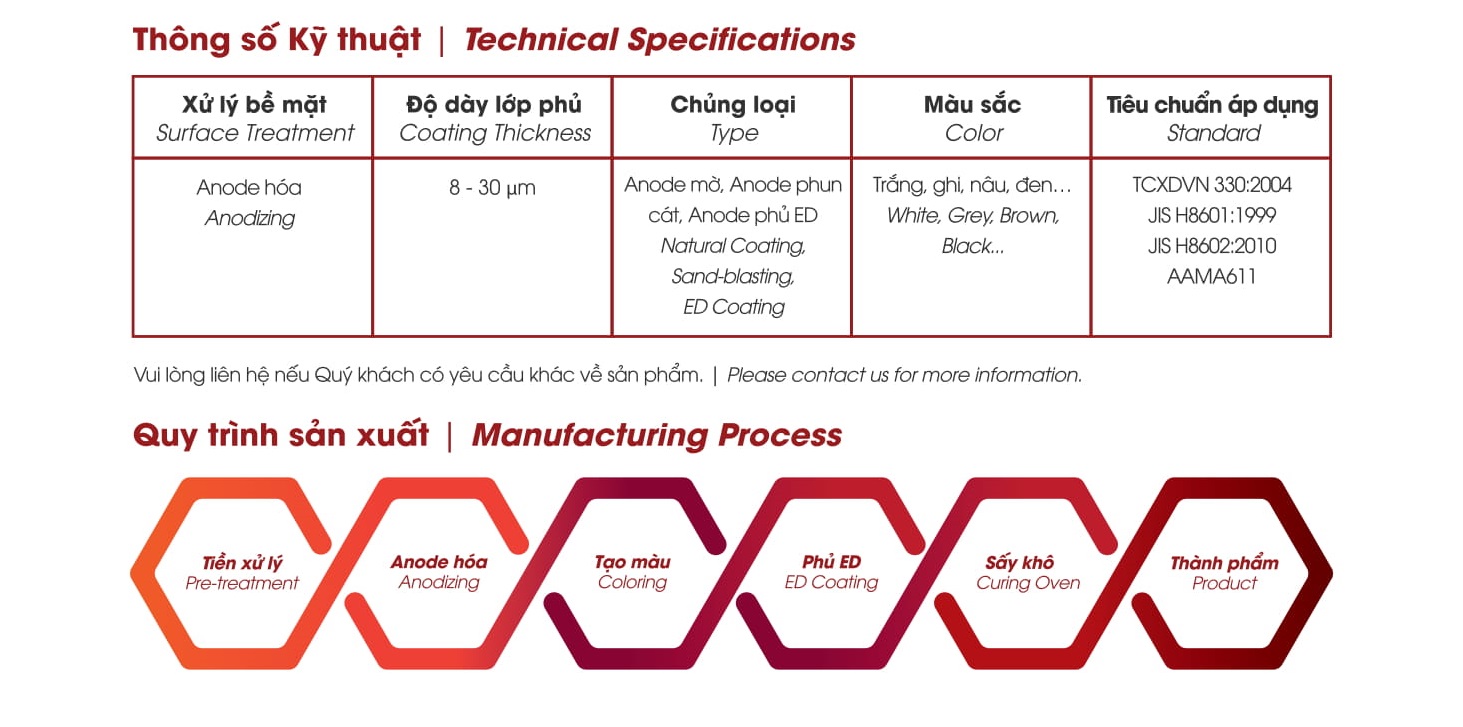

KIMSEN is proud to bring high quality aluminum extrusion, components & modules which meet international standards

With complete line of equipment and strict quality management process, KIMSEN Aluminum commits to providing our customers with the highest quality products that meet all the standards in accordance with current regulations and international standards such as JIS H4100:2015, EN 755-9:2016. KIMSEN's anodizing products consist of three main types: Natural Coating, Sand-blasting and ED Coating with a wide range of colors: white, grey, brown, black... to meet the diverse requirements of the market.

The anodizing tank

For specific advice, please contact Hotline 0243 795 7410 or email info@kimsen.vn

KIMSEN INDUSTRIAL CORPORATION

Head Office & Factory: Yen Phong Industrial Park, Yen Phong Dist., Bac Ninh Pro., Vietnam

Hanoi Office: 14th floor, TTC Tower, No. 19 Duy Tan Str., Cau Giay Dist., Hanoi, Vietnam

Hotline: 0243 795 7410

Email: info@kimsen.vn

*Reference: https://www.3erp.com/blog/everything-about-anodizing-aluminum/

Chia sẻ:

Chia sẻ: