Anodizing

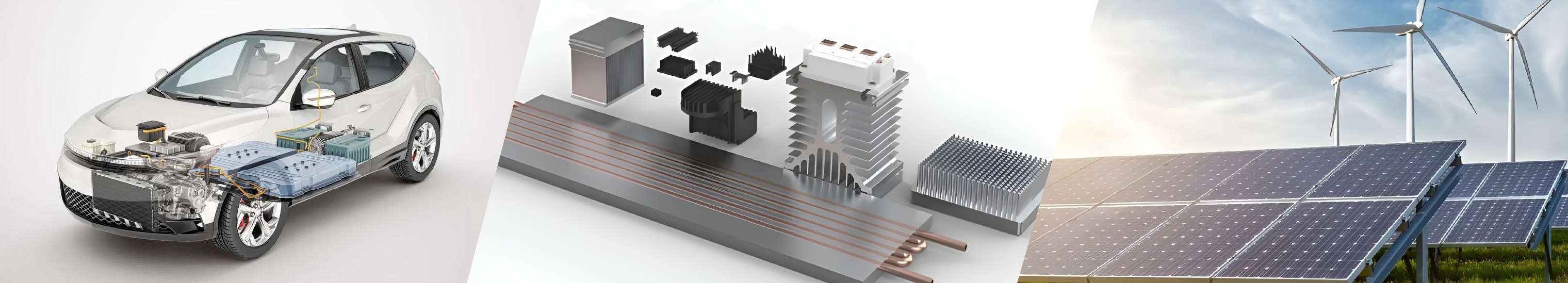

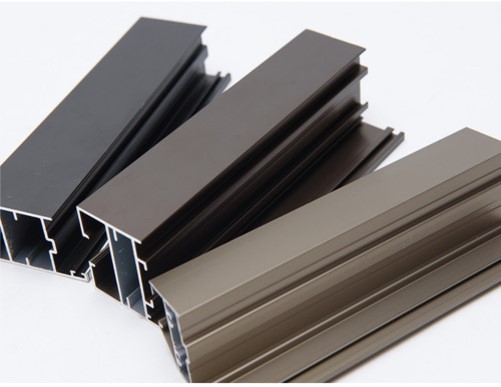

Anodizing is a method for surface treatment through electrochemical processes to create a stable surface with a certain hardness suitable for use in the industrial field.

ADVANTAGES:

- Durability: Most anodized products have an extremely long life span and offer significant economic advantages through maintenance and operating savings. Anodizing is a reacted finish that is integrated with the underlying aluminum for total bonding and unmatched adhesion.

- Color stability: Exterior anodic coatings provide good stability to ultraviolet rays, and are easily repeatable.

- Aesthetics: Anodizing offers a large increasing number of gloss and color alternatives. Unlike other finishes, anodizing allows the aluminum to maintain its metallic appearance.

- Cost: A lower initial finishing cost combines with lower maintenance costs for greater long-term value.

- Health and safety: Anodizing is a safe process that is not harmful to human health. An anodized finish is chemically stable, will not decompose; is non-toxic; and is heat-resistant to the melting point of aluminum (1,221 degrees F).

Since the anodizing process is a reinforcement of a naturally occurring oxide process, it is non-hazardous and produces no harmful or dangerous by-products.

Type: Matte, Natural, ED coating

Average thickness: 6 – 18 μm

For more information, please contact us via Hotline: +84 93 867 6005 or email: info@kimsen.vn

.jpg)

Images source: Internet