Understand the Difference Between Cast Aluminum and Extruded Aluminum

What is Die Casting?

.jpg) (Image source: Internet)

(Image source: Internet)

Die cast aluminum products are made by melting aluminum ingots, injecting the molten metal into a die mold using a power cylinder or piston, and then letting the aluminum solidify into the die mold’s shape as it cools. While the process is somewhat more complex in practice - including steps like adding alloying elements and deburring - the general principle is relatively straightforward.

Die castings can be done in a wide range of sizes and can accommodate complex geometries — like automotive engine blocks, for example. After creating a tool steel die mold, you can cast the product numerous times before the mold deteriorates and you need to replace it.

(Image source: Internet)

(Image source: Internet)

The number of times you can reuse a mold depends on the shape of the part, the allowable tolerances for the end product, and processing conditions.

What is Extruding?

Extruded aluminum products are made by forcing a heated aluminum billet through a die to produce the desired cross-section. The extrusion can then be cut to an appropriate length and subjected to further processing - like machining bolt holes or fitting together different parts for the final product.

Aluminum extrusions are well-suited to high production outputs, where they rapidly produce reliable, high-strength aluminum products as a result of the work-hardening that occurs during forming.

Which Process is Better for Your Project?

Both die casting and aluminum extrusion have excellent advantages and a few disadvantages that make them better suited for certain applications. To help you decide which process is best for you, take a look at the side-by-side comparison below:

| Die Casting |

Extrusion |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Conclusion

Both die casting and extrusion can be excellent methods for making your aluminum products. The choice you make ultimately depends on the specifics of your project, as you can expect different mechanical properties and manufacturing costs with each processing method.

(Reference: gabrian.com)

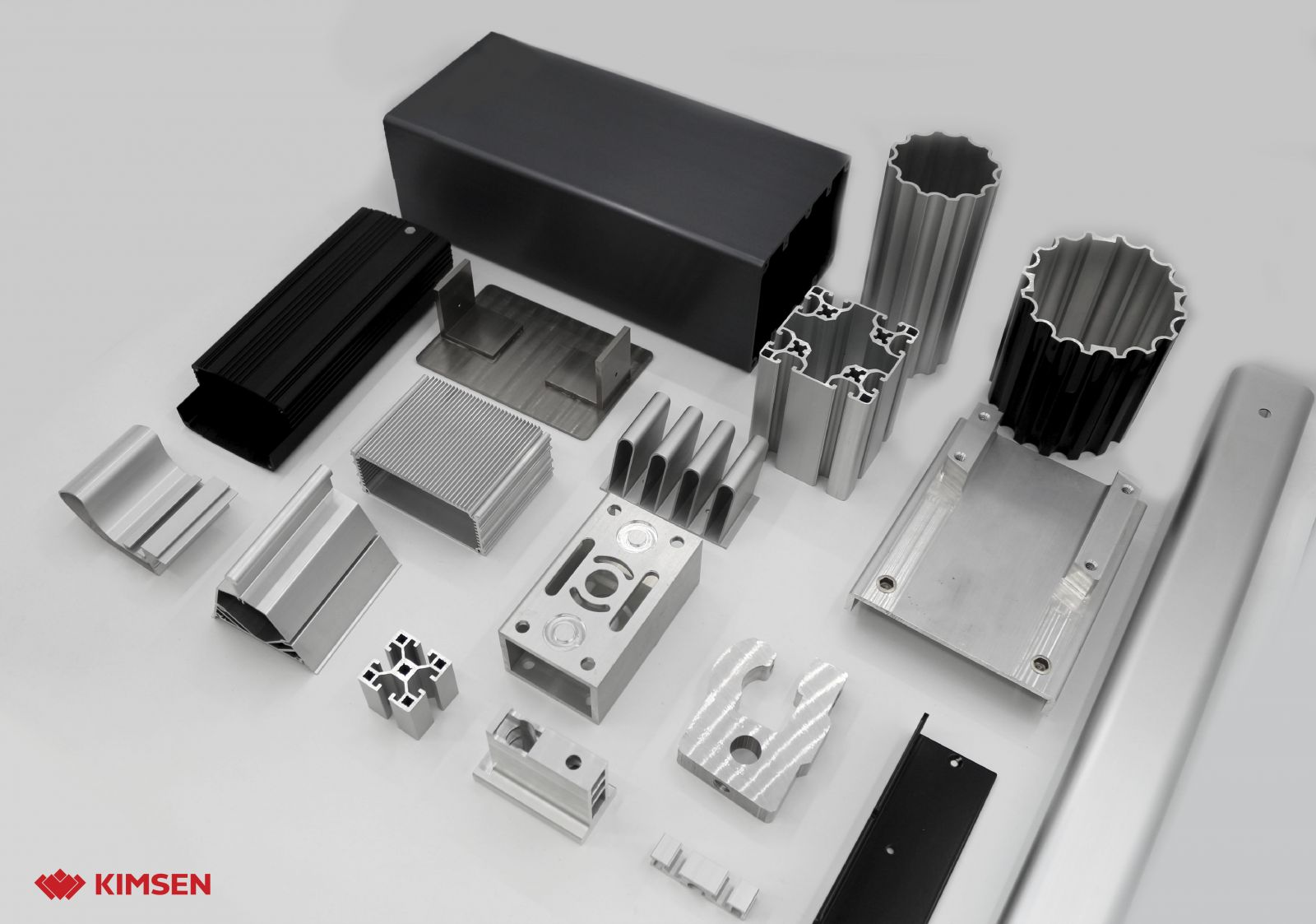

KIMSEN is proud to bring high quality extruded aluminum, components & modules which meet international standards

Currently, KIMSEN is operating 3 modern technology aluminum extrusion lines with wattage of 920 UST, 1100 UST & 1880 UST, which are able to produce approximately 1.000 tons/month.

Aluminum extrusion lines with wattage of 920 UST, 1100 UST & 1880 UST

Aging furnace

For specific advice, please contact Hotline 0243 795 7410 or email info@kimsen.vn

Chia sẻ:

Chia sẻ: