The Best Aluminum Alloys for Extruded Heat Sinks

Advantages of using Aluminum over Copper in Heat Sinks

While copper has higher thermal conductivity (approximately 60% higher than aluminum), its main drawback is its lack of versatility, high density and high cost. Aluminum scores over Copper, as it’s lightweight, extremely versatile and relatively lower in cost. Moreover, aluminum has good conductivity and can be extruded while copper heat sinks have to be machined and skived. Thus, Aluminum is the material of choice for heat sinks and extrusion is the most common manufacturing process. Custom aluminum extrusions are ideal for most applications and the material of choice for heat sinks owing to their affordability and versatility.

Choosing the Best Aluminum Alloy for Heat Sinks

While one would think that the alloy with the highest thermal conductivity should be used for heat sinks, we must consider its durability. The temper of the alloy used is also an important consideration. The Aluminum alloy 1050A has a higher thermal conductivity of 229 W/m•K, but it is too soft mechanically to be used for heat sinks. One should opt for aluminum alloys in the 6000 series as they are strong, malleable, and are ideal for extrusion. Out of these, the Alloys 6060, 6061 and 6063 series are the most preferred for designing heat sinks. The following table will give us a better idea of the thermal conductivity of different aluminum alloys:

| Aluminum Alloy | Thermal Conductivity(W/m•K) |

| 1050 | 229 |

| 6060 | 166 |

| 6061 | 152 |

| 6063 | 201 |

The Ideal Aluminum Alloy for Your Project

As the thermal conductivity between 6000 series alloys is relatively minimal, one can make an informed choice by maximizing the surface area of the heat sink and optimizing airflow. One should make sure that the heat sink conforms to the hot component and leave the tiniest possible gap. While 6063 is versatile and cost-effective, 6061 has higher tensile strength, up to 240 MPa. (Tensile strength of 6063 is up to 186 MPa). 6061 Alloy (with magnesium and silicon) is a precipitation-hardening alloy with excellent mechanical properties and weld-ability.

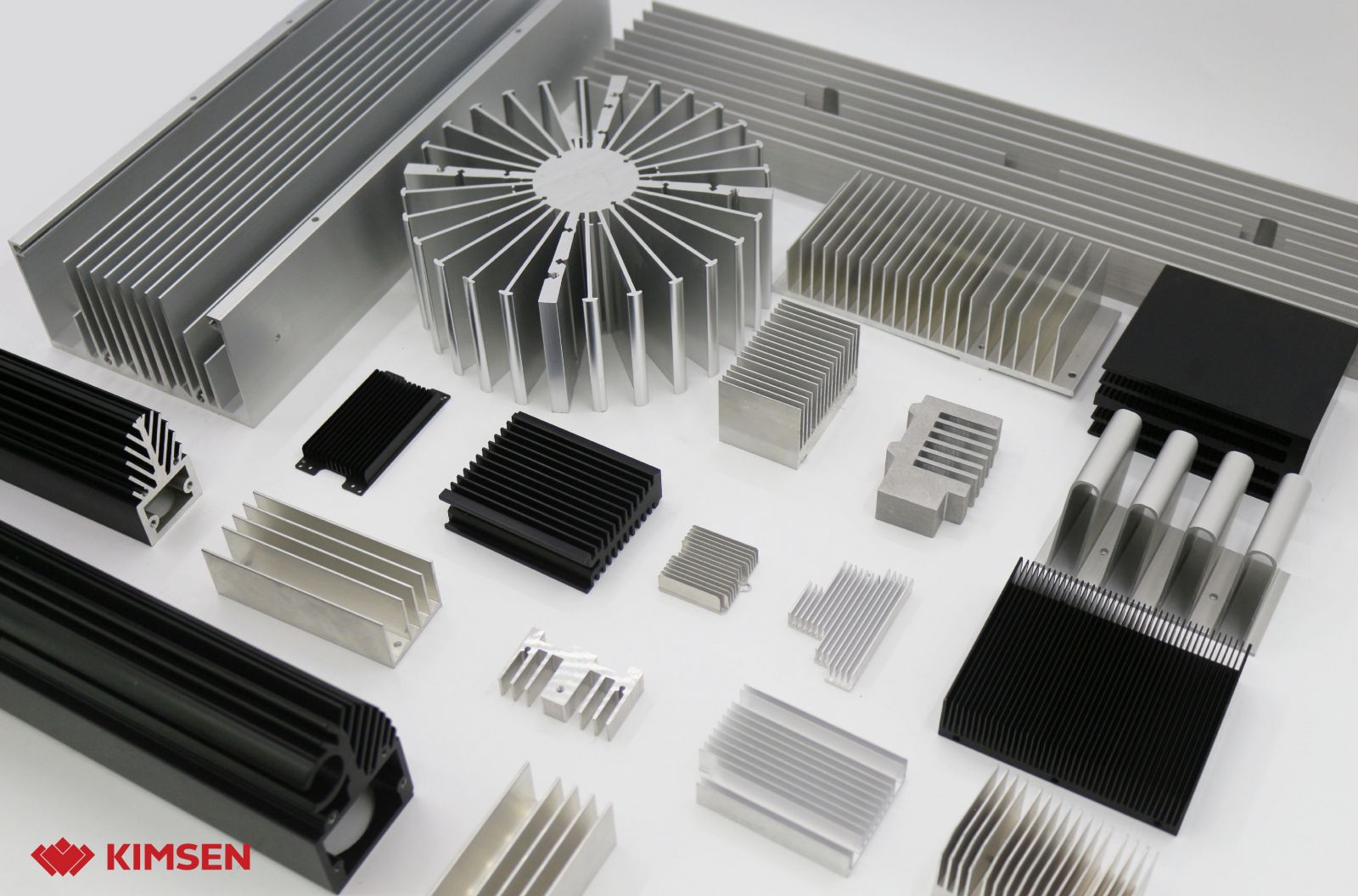

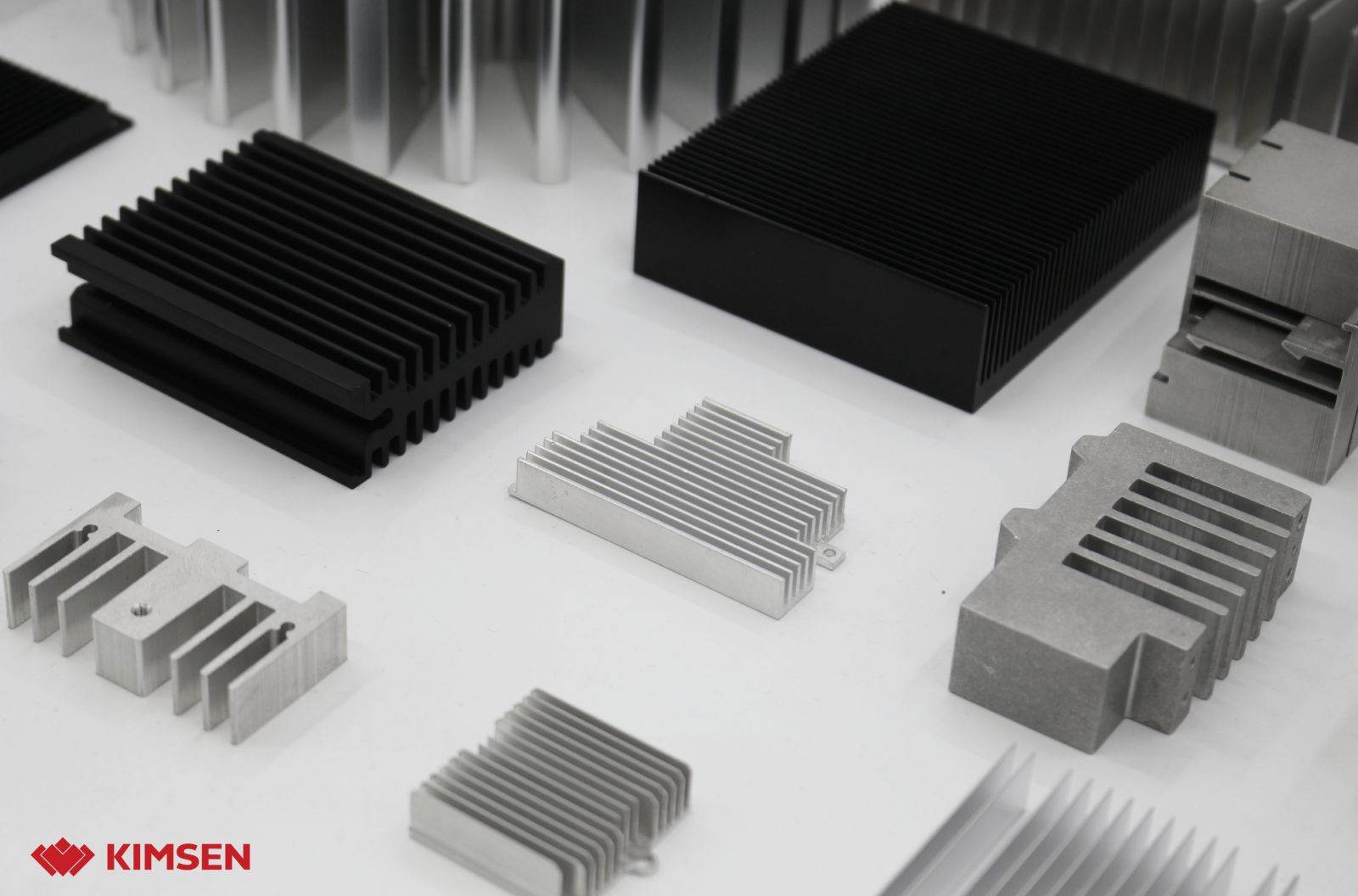

KIMSEN is proud to bring high quality extruded aluminum, components & modules which meet international standard

-01.jpg)

Currently, KIMSEN is operating 3 modern technology aluminum extrusion lines with wattage of 920 UST, 1100 UST & 1880 UST, which are able to produce approximately 1.000 tons/month.

For specific advice, please contact Hotline 098 280 0060 or email info@kimsen.vn

Source: gabrian.com & odmetals.com

Chia sẻ:

Chia sẻ: