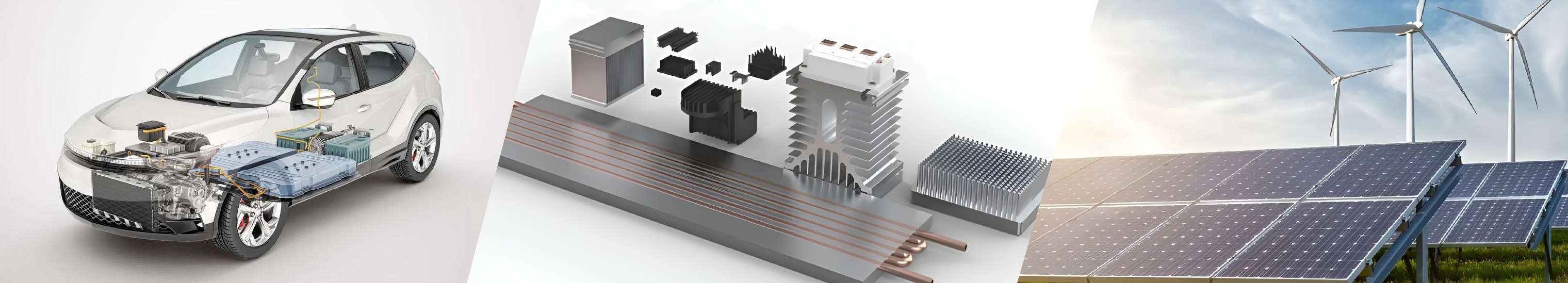

Other Machining Techniques

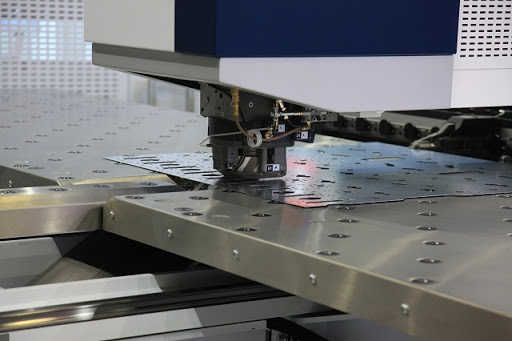

1. Punching

What is Punching?

Punching is a method of pressure machining which uses pressure to create holes in the workpiece, the excess material when making holes will be scrap, the rest is the formation. This method uses a punching mold with a pestle and a mortar with a sharp edge to make holes in the product.

Images source: Internet

Advantages of Punching method

- Multiple holes can be created at the same time

- The product is stable in both quality and geometric shape

- Optimal application for machining batch, mass, standard product

- Save machining time, take less labor and optimize production process

- High economic efficiency, less waste products in production

Application of Punching method

- Punching has important applications for the treatment of sheet metal for technically sophisticated products, such as for aerospace or electronics.

- Create parts for the metal and construction industry, spare parts manufacturing industry...

- Some common punches: flat punch, rotary punch.

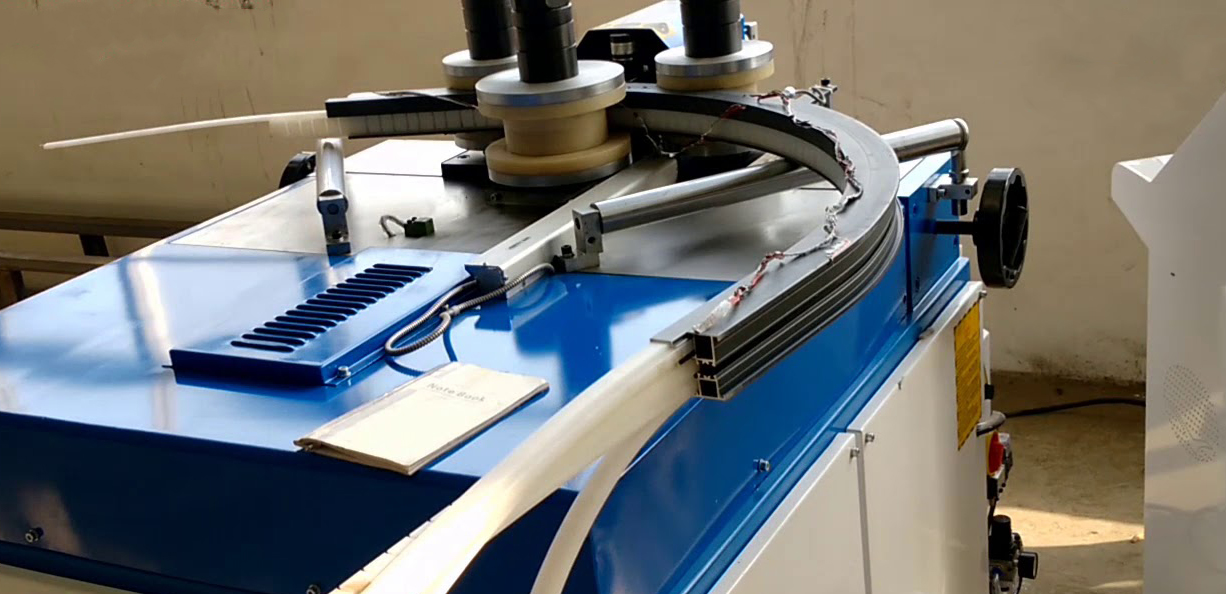

2. Bending

What is Bending?

Bending is a method that uses a specialized tool to bend metal to create different curves.

Images source: Internet

Advantages of Bending method

- Can fabricate various curvature deformation such as C, U, S, circle and spring

- Bends materials such as iron, copper, aluminum, and profile materials. Especially in the manufacture of aluminum doors.

Images source: Internet

For more information, please contact us via Hotline +84 93 867 6005 or email info@kimsen.vn