Laser Engraving

Laser metalworking technology using Laser cutting machines. Taking advantage of the heat and wavelengths generated by the convergence of laser beams. Laser cutting machines will perform cutting, whittling and etching on the metal. Currently, lasers are the most commonly used modern mechanical processing method, which can be used in a variety of metalworking applications.

Outstanding advantages of Laser engraving technology:

* Can engrave on all different materials such as aluminum, copper, steel, stainless steel, plastic, paper cut...

* Highly automated, drawing programming on intelligent control software to create absolute accuracy

* Engraved pattern in a short time, with high accuracy and evenness. Does not damage or impair the quality of the material

* Fine engraved details, no further machining is required

* Finished products have high aesthetic

* Cost-effective

Images source: Internet

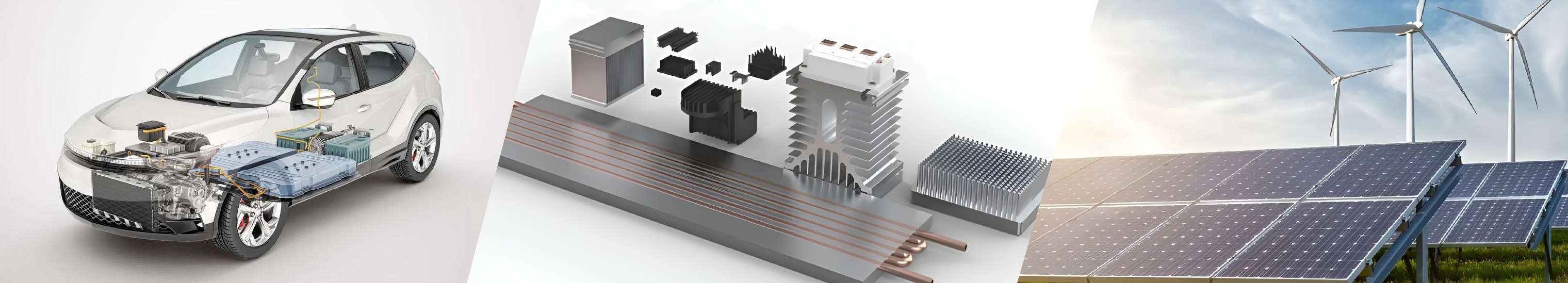

Laser engraving technology applications:

Laser engraving technology is applied in many different fields such as marking or logo engraving, printing production information, manufacturing date, expiry date or engraving metal molds, stainless steel grooving, laser engraving or painting aesthetic pattern details...

Laser application in barcode engraving (Images source: Internet)

|

Laser wavelength |

1064nm |

|

Quality beam |

< 1.3m2 |

|

Tolerance |

±0.001mm |

|

Smallest font size |

0.1mm |

For more information, please contact us via Hotline: +84 93 867 6005 or email: info@kimsen.vn

-01.jpg)