Largest NFL Stadium in History Uses Aluminum in Critical Structures

Working as the project manager for the roof canopy, Zahner provided support to HKS, the architectural firm that designed it. Zahner used their aluminum knowledge and engineering expertise with panel specifications, anodization, custom colors, perforations, and attachment points to create the impressive roof.

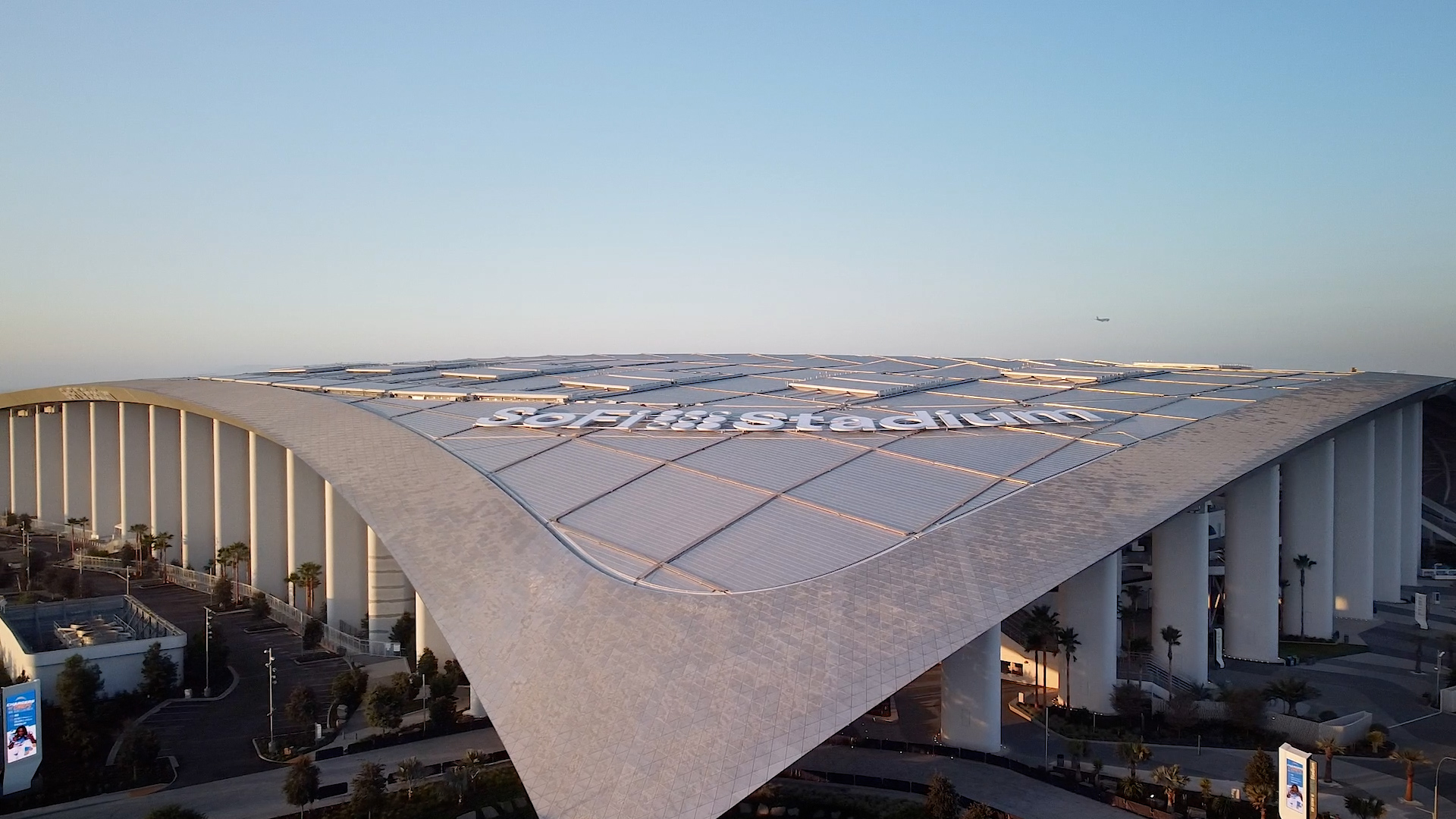

Sofi Stadium in Inglewood, California

The panels attach to an aluminum lattice support system, which attaches to the steel structure surrounding the stadium that (along with the roof) make up the canopy. The independently supported canopy (separate the stadium bowl structure) covers the stadium, allowing for wind circulation, diffused lighting, and protection sun and rain.

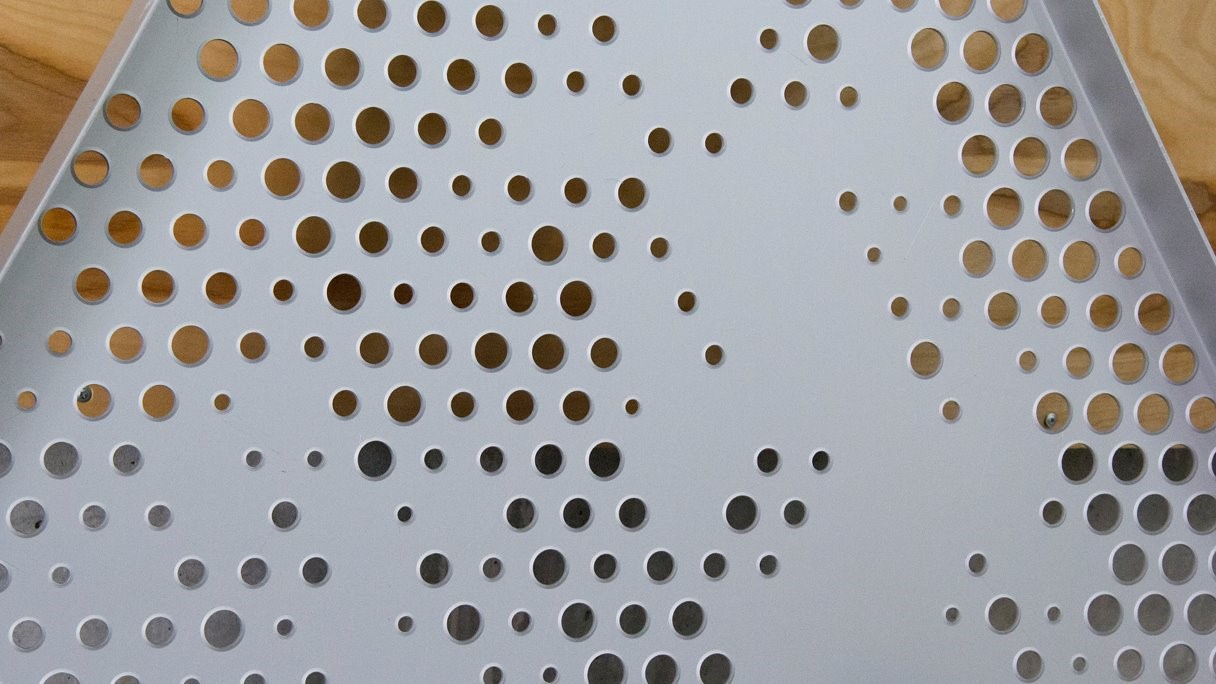

A close-up of one of the exterior aluminum panels

The unique Frost White anodized finish on 1/8 inch thick aluminum panels used for the SoFi Canopy was developed the collaboration of Zahner, AaCron, Novelis, and Metalwest, and has never been used before in any other project. The exclusive Frost White was developed specially to stand out against the blue sky, but also to have a matte finish so as not to create dangerous glare for air traffic flying directly overhead to and the Los Angeles International Airport.

/cdn.vox-cdn.com/uploads/chorus_image/image/69186619/1232467098.0.jpg)

Aluminum canopy of SoFi stadium

“Other materials for the canopy were considered very early on, but once the white anodize option came into play, aluminum was the choice and we engineered the panels (thickness, return dimensions, etc.) around the aluminum,” said Angela Orscheln, vice president of Operations at Zahner. “Weight and strength are nice benefits, but ultimately it was the finish — and the budget is of course always a factor.”

With 3.1 million sq ft of space covered by the canopy, it is now one of the world’s largest indoor-outdoor venues, containing a 70,000-seat stadium, as well as a 6,000-seat smaller venue and a 2.5-acre plaza.

Inside SoFi Stadium has a seating capacity of 70,000

A Massive Undertaking

Mark Williams, principal in charge for the project and business development director for sports at HKS, said in a recent Forbes.com feature that replicating the Southern California indoor-outdoor design philosophy was the driving idea, but it had never been done on this scale before. The entire stadium project cost over 2.5 billion dollars.

To begin, a veritable army of diggers had to excavate 190 million cubic ft of earth to create a 100 ft deep pit. The pit was created for the stadium bowl to sit in. If it had been built above ground the top of the stadium would’ve reached into restricted air traffic space. Steel beams and girders were used to form the stadium’s skeleton with 3,300 slabs of concrete to form the stadium stands.

Since SoFi was built at close proximity to the Newport-Inglewood fault line, the entire project had to take into consideration the possibility of future seismic activity. It was essential to build the stadium under earthquake safe guidelines. Thirty seven steel earthquake-resistant columns support an enormous 20,000 ton steel truss that holds a mesh of wire cables winched tight to hold the roof canopy, which supports more than 300 semi transparent panels that workers laid in sections to create the largest roof of its kind. The translucent roof lays at the top of the stadium with the aluminum canopy surrounding it on all sides. Some of the translucent panels at the top are moveable for airflow.

The pit was created for the stadium bowl to sit in

To prevent roof collapse in the event of seismic activity, the steel support columns that hold the roof are supported by anchors below ground-level known in construction as a “dead man.” Huge blocks of reinforced concrete are tethered to each column by a long concrete arm, and through each anchor the team threaded six bundles of strong steel cables that grip the base of columns and essentially tie the structure to the ground. Every column has two anchors that overlap each other to form a giant concrete web. The roof alone weighs over five million pounds. A steel truss weighing 20,000 tons supports the one million sq ft roof.

Aluminum Frames in Record Breaking LED Screen

The stadium-sized, record breaking video board measures 360 ft long and 45 ft high. The video board is not only longer than the field, but curves around the stadium to create an enormous continuous loop of video screen. It’s the world’s first double sided video board with 80 million LEDs covering both the outside and the inside of the structure. Suspended the roof, the enormous screen will allow every single seat in the stadium to get an unobstructed view of the field to see the game up close.

Aluminum Frames for Led screens

In Utah, the company Primsview transformed mile after mile of aluminum sheets into cabinets/frames to hold the LED screens. There are 300 aluminum frames that make up the video board in its entirety and each frame with added LED panels will weigh in at 1,800 pounds.

The video board’s giant steel support frame was assembled on the floor of the stadium where the 1,300 frames/screens were attached. Each aluminum frame was fixed at just the right angle to create a gradual curve, and the interior was filled with 268 enormous speakers. All in all it weighs 2.2 million pounds and is connected to the roof with 14 steel cables.

Time for Football

The stadium will host two NFL teams, the San Diego Chargers and the Los Angeles Rams. Construction was completed just in time for a virtual ribbon-cutting ceremony on September 8th. The ribbon-cutting ceremony kicked off SoFi Stadium’s first year, and celebrated the hard work of the tens of thousands of people that brought this venue to life the time it first broke ground in November 2016.

The first game at SoFi was held on September 13, 2020 where the LA Rams defeated the Dallas Cowboys in a 20-17 win. SoFi Stadium will be the site of Super Bowl LVI in 2022, the College Football Playoff title game in 2023 and the opening and closing ceremonies of the 2028 Olympics.

Source: https://www.lightmetalage.com/news/industry-news/applications-design/

Images source: Internet

Chia sẻ:

Chia sẻ: