Jigs and Fixtures – All You Need To Know

Jig

- Jig may be defined as a work-holding device generally used in a drill press in conjunction with drill bushings for guiding the tools so that drills will produce holes only where the bushing is located in the drill Jig.

- Jig may be also defined as a device used in mass production for increasing productivity by correct location & firmly holding the workpiece as well as guiding the cutting tool.

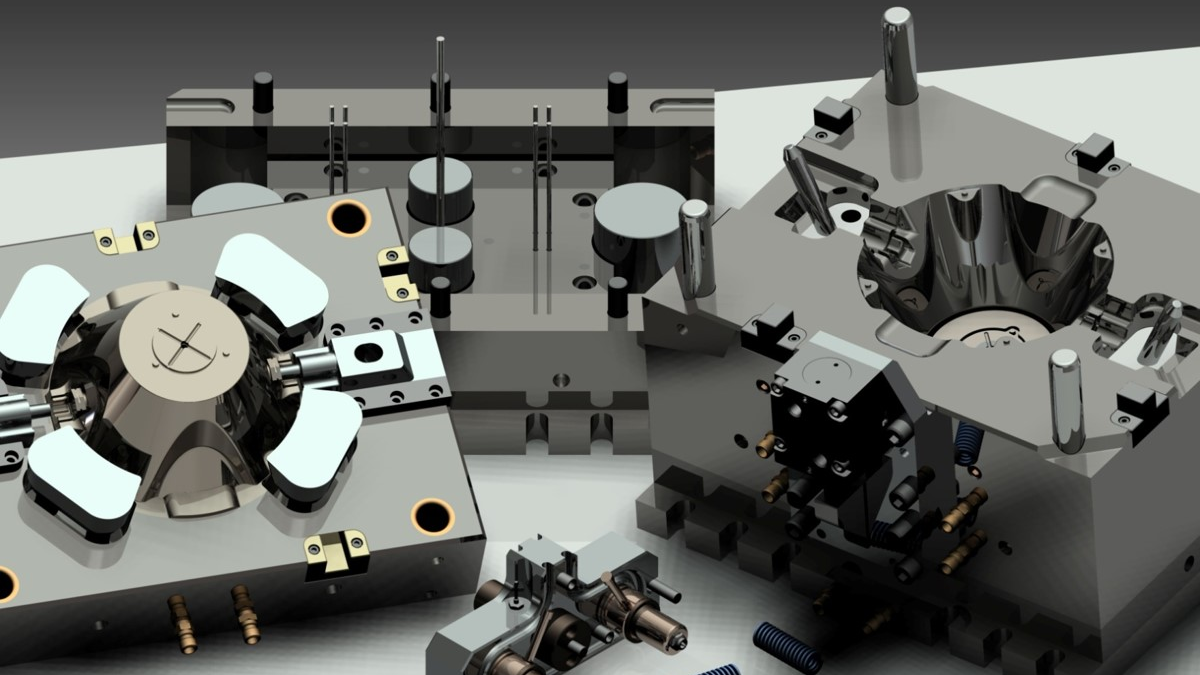

Fixture

- Fixture may be defined as a device used to increase manufacturing efficiency and productivity in mass production.

- It locates the workpiece incorrect position and holds it firmly but it does not have provision for guiding the cutting tool.

- Set blocks and feeler or thickness gauges are used with Fixtures to reference the cutter to the workpiece.

Difference between Jig and Fixture

.png)

Jig

- It guides the cutting tool.

- It is mostly attached to the machine table.

- It is generally light in weight than the Fixture.

- Jig feet is used in its construction.

- Bushes are used in a Jig for guiding the cutting tool.

- It is specially used for drilling, reaming & boring operations.

- Jig is widely used on drilling machine.

- Jig cost is more.

- Jig designing is complex.

Fixture

- It does not guide the cutting tool.

- It is always attached to the machine table.

- Fixture is generally heavier than the Jig.

- In its construction such feet is not used.

- Bushes are not used in Fixtures.

- It is specially used for milling, turning, grinding operations.

- Fixture is widely milling, grinding machines.

- Fixture cost is less as compared with the Jig.

- Fixture designing is less complex.

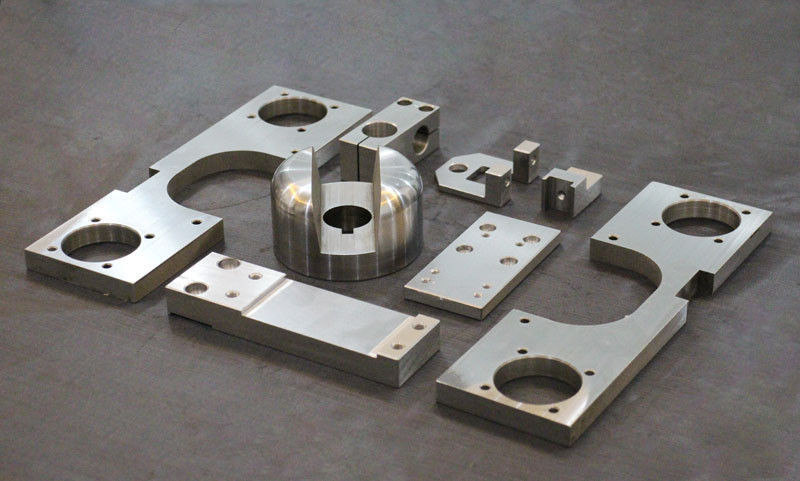

Main elements of Jigs and Fixtures

- Body: It is a plate, box or frame type structure where components are located for machined. The body should be quite sturdy and rigid.

- Locating elements: These elements are located at workpieces in the exact location for cutting tools.

- Clamping elements: These elements firmly secure workpiece in the located position.

- Grinding and setting elements: These elements guide the cutting tool if Jig and help in proper tool acting in case of the Fixture.

- Positioning elements: These have different types of fastening devices and it is used to secure Jig or Fixture to machine at the proper position.

- Indexing elements: It is not always provided. But for many workpieces, it is indexed for different positions to order perform machining operations for different surfaces or different locations. In some cases these elements have to incorporate in Jig or Fixture.

Advantages of using Jigs and Fixtures in Mass Production

- This eliminates the making out, measuring and other setting methods before machining.

- This increases the machine accuracy as the workpiece is automatically located and the tool is guided without making any manual adjustment.

- It is possible to make identical parts and also these parts are interchangeable. This also helps in assembly operation.

- This minimizes the expenditure on quality control of finish products.

- It minimizes the overall cost of machining by making fully or partly automating the process.

- This increases the production capacity as there is a number of workpieces machined in a single set up and in some instance, a number of tools may made operate simultaneously. The handling time is less as it has a quick setting for locating the work. Speed, feed, and depth to cut for machining can increase due to high clamping rigidity of Jigs and Fixtures.

- This reduces the operator’s labor as there are less handling operations.

- A semi-skill operator can operate the setting operations of the tool and work is machined which saves labor costs.

- This minimizes the expenditure on quality control of finish products.

- It minimizes the overall cost of machining by making fully or partly automating the process.

Source: theunboxfactory.com & alldifferences.net

Images source: Internet

Chia sẻ:

Chia sẻ: