Instructions To Improve The Weather-Ability Of Powder Coatings

Powder coatings are principally made out of resins, binders, additives, and color pigments. With time going, the properties of the coating film on the surface of aluminum profiles will decrease gradually because of the effects of natural factors for example sunlight, rain, oxidation, cold and heat changes, and microorganisms. This process is called “aging”. The capacity of powder coatings to inhibit or retard natural aging is called natural aging resistance, or aging resistance. Otherwise called weather resistance.

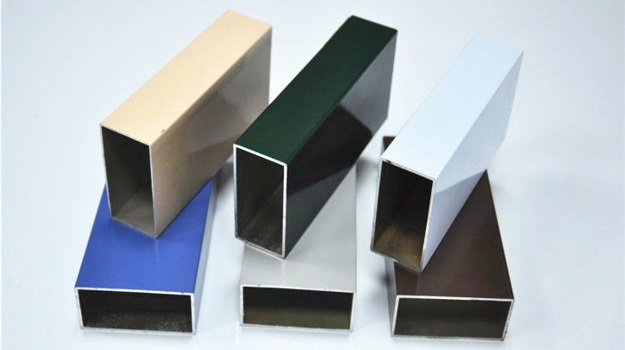

Images source: Internet

There are many numerous components that influence the weather-ability of powder coatings. It includes the inner factors such as the performance of resins, binders, additivers and color pigments. As well as the process conditions and curing degree of powder coatings. There are also the use of film environment such as the role of sunlight (mainly ultraviolet), the composition of the atmosphere (oxygen, ozone, industrial smoke, etc.), humidity (including acid rain, salt fog, etc.), temperature changes and other external factors.

Materials

To improve the weather capacity of powder coatings, the initial step is to choose the raw materials which can meet the requirements of aluminum profile industry. Furthermore, the qualified raw materials should also meet different properties of the coating film.

1. Resin

Since resin is the main film-forming material of powder coatings. And it’s the most important component that determines the properties of films. The selection of Resin is very important.

Images source: Internet

2. Binder

Despite the fact that Curatives of HAA system is well known. Its disadvantage is that the by-product is formed in the curing reaction. And pinholes and porcine pores are easy to be produced in thick spraying. The yellowing resistance and durability of overbaking film are not as good as those of TGIC system. At present, it is hard for aluminum profile industry to accept these disadvantages of HAA system. Most powder manufacturers have not tackled these problems. So the TGIC system is still the main powder coating for aluminum profile. The curing agent TGIC also has an effect on the weather ability of powder coatings.

3. Pigment

The impact of pigment on the weather capacity of powder coatings is the most significant factor in raw materials except resin. Since pigment will fade during use. Even if one color is used, in the market, there are many kinds of pigments. Also, the properties of various pigments (such as hue, coloring power, covering power, weather ability and heat resistance) are altogether different. This gives us a great difficulty to pick.

Table: Comparison of Advantages and Disadvantages between Inorganic Pigment and Organic Pigment

|

Advantages |

Disadvantages |

|

|---|---|---|

|

Inorganic Pigment |

Good heat resistance, strong chemical inertia, strong hiding power, good weather resistance, color stability |

Poor coloring, limited range of colors, not bright, some toxic |

|

Organic Pigment |

Strong coloring, good transparency, bright color, broad range of colors. Non-toxic |

High cost of raw materials, poor heat resistance, poor hiding power |

4. Additiver

The important function of additiver is to improve the hardness, rigidity and scratch resistance of coating film after it is added to powder coatings. At the same time, it is helpful to improve the storage stability, looseness and electrification of powder coatings. Barium Sulfate is the most normally utilized additiver for aluminum profiles. In this manner, to guarantee the weather ability of coatings, it is important to use high purity barium sulfate as additiver.

Images source: Internet

5. Crosslinker

In powder coatings formulation, the amount of crosslinker is very small. But in general powder coatings formulation composition, crosslinker is an indispensable component. And it plays a decisive role on film appearance and some properties. To improve the weather ability of powder coatings, consider using anti-aging wax powder and matting agent is available.

Formula Structure

The appropriate amount of curing agent is designed by calculating the acid value of polyester resin in powder coatings and the hydroxyle equivalent of curing agent. The optimum amount of curing agent is used to fully solidify make the coatings when curing, which is verified by accelerated aging test. To achieve the best weather resistance.

On the premise of satisfying the properties of powder coatings, reduce the types of raw materials, especially the materials that have negative effect on the weather ability of coatings. On the premise that the coating film doesn’t affect the covering power, hardness and wear resistance. The amount of pigments and additivers in the formulation (especially the pigments with large oil absorption capacity) should be reduced appropriately. So that the pigments in the formulation can be complete covered by resin in the melting and mixing process. In the course of using the coating film, decrease the color change of the pigment. To improve the weather ability of the coating film.

Images source: Internet

Manufacturing Process

The manufacturing process of powder coatings consists mainly of four stages: pre-mixing, melting extrusion, crushing and grading crushing. The two processes of pre-mixing and Melt extrusion have great effect on the weather ability of powder coatings.

The reason of premixing is to make the raw materials in the powder coating formula disperse evenly. The purpose of Melt extrusion is to make the different components in the composition of the powder coating mix evenly. To improve the weather resistance, in the melting extrusion stage, under the premise of no gelling particles, the temperature of extruder should be raised properly (especially under the condition of lower temperature), so that the resin can melt into a kind of fluid. To guarantee that the pigment can have a good wetting and obtain the maximum shear force. And it is conducive to high dispersion of pigments, so that the components into a uniform system.

While ensuring the production progress, the extrusion speed can be appropriately reduced to ensure that the materials have sufficient melting and mixing time. Thus improving the mixing effect. So that the pigments and additivers in the powder coatings are fully covered by resin. And the particles of various raw materials are dispersed evenly. Especially the curing agent and resin can be mixed according to the proportion of the formulation. The film can be solidified when cured, thus increasing the surface compactness of the film. Finally, the weather ability of the powder coating is improved.

Curing Conditions

Just when the powder coating is cured, the polymer chain of the resin will be fully cross-linked with the curing agent. And the Physical Chemistry Properties will reach the best state. Weather resistance is no exception. In this way, to improve the weather ability, the powder coating must be completely cured. Also, well controlling the temperature and time.

KIMSEN is proud to bring high quality aluminum extrusion, components & modules which meet international standards.

We provide surface treatment solutions applied with the most advanced technology:

- Anodizing

- Powder Coating

- NCP (Non Chrome Pretreatment)

- Wood grain coloring

- Sand blasting

>> For more information about our Powder Coating services

For specific advice, please contact Hotline +84 93 867 6005 or email info@kimsen.vn

KIMSEN INDUSTRIAL CORPORATION

Head Office & Factory: Yen Phong Industrial Park, Yen Phong Dist., Bac Ninh Pro., Vietnam

Hanoi Office: 14th floor, TTC Tower, No. 19 Duy Tan Str., Cau Giay Dist., Hanoi, Vietnam

Hotline: +84 93 867 6005

Email: info@kimsen.vn

*Reference: https://haluminium.com/Product/how-to-improve-weather-ability-of-powder-coatings/

Chia sẻ:

Chia sẻ: