Industrial Use of Aluminum Casting

From aerospace to ovens, aluminum‘s multiple properties and characteristics have proven it to be a reliable and strong metal that has a long usage life as well as the ability to be worked and shaped into any form to fit a design. Aluminum can be combined with over 270 minerals to enhance its performance and benefits.

Aircraft Components

Since the end of the Second World War, the aerospace industry has relied on aluminum parts, which is approximately 80% of the structure of an aircraft. Cast aluminum parts have the properties and characteristics that are demanded by the industry. Aircraft producers have realized substantial savings through the use of cast aluminum components.

Cast aluminum airline handrail

Automotive

As the pressure has increased to improve gas mileage for vehicles, auto manufacturers are continually searching for ways to include high strength aluminum castings in their product designs. To assist in the process, aluminum casting producers have been perfecting and improving their methods and techniques to streamline the production processes to increase output at a reasonable cost.

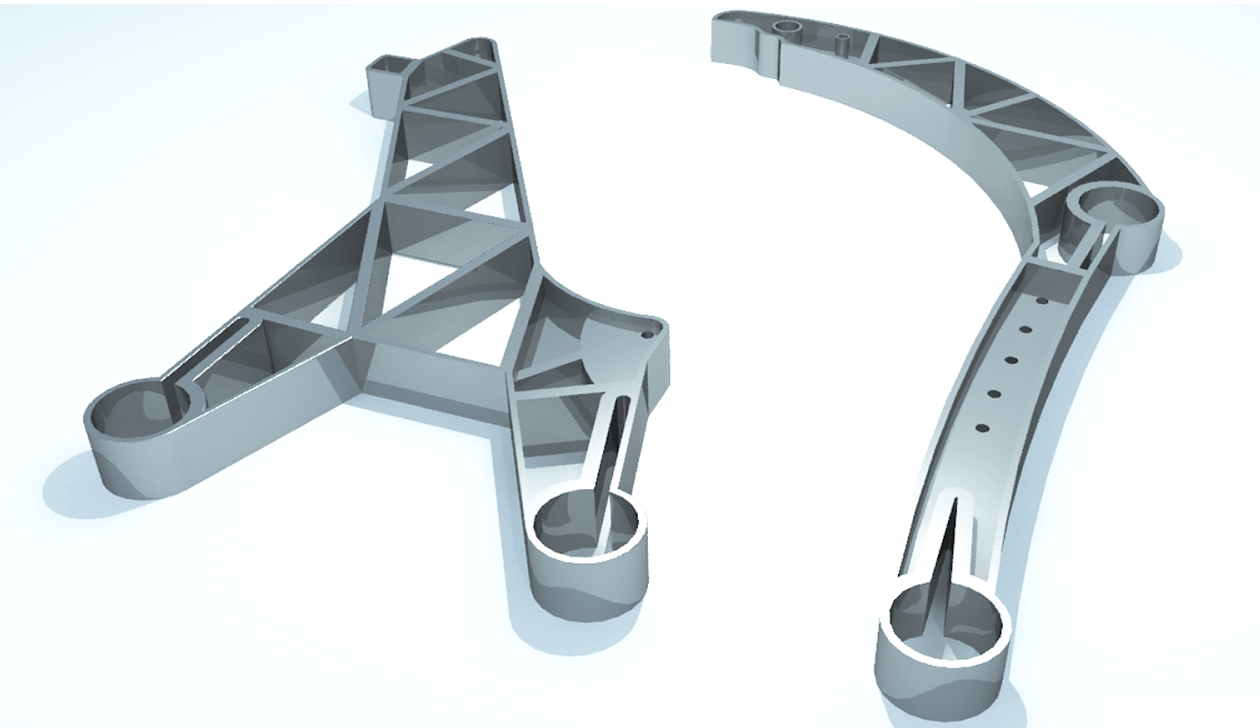

Examples of cast aluminum automotive parts

Aluminum cast parts for automobile manufacturing include oil pumps, water pump housings, connectors, transmission parts, and a wide variety of brackets. The durability and reliability of aluminum cast parts has made them an essential part in auto design improvements and innovations.

Lighting

Aluminum cast lighting produces lights that are non-toxic and lightweight. The corrosion resistance of aluminum cast light fixtures makes them ideal for outdoor use. Two popular processes for producing light fixtures are permanent mold and gravity casting, which makes it easier to work with the final product and can be used for lighter forms of aluminum. As with the production of automotive components, the production of light fixtures using cast aluminum is economical and time saving.

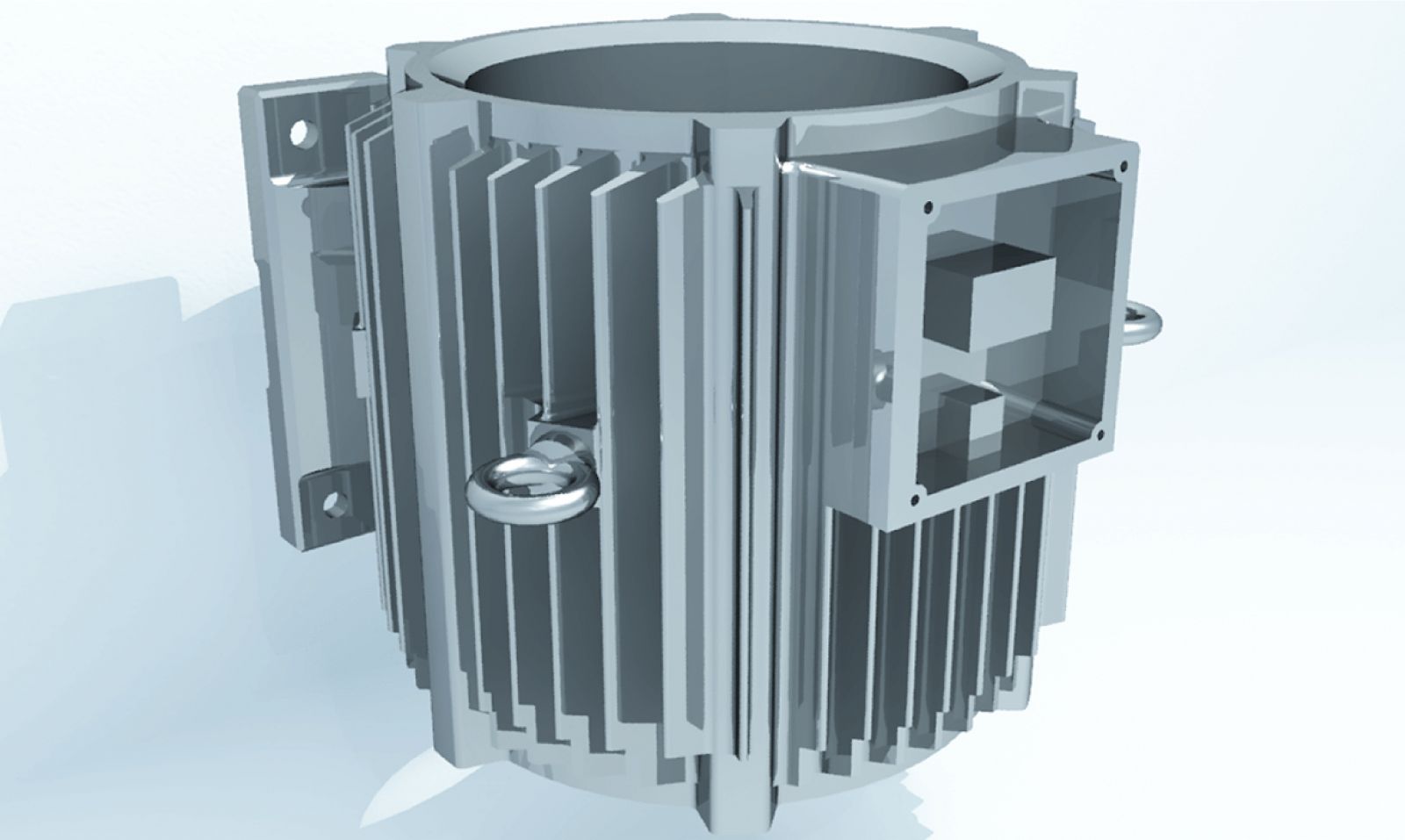

Die casting Aluminum LED light housing

Each of the many production processes can easily be adapted to produce any design with the stability and characteristics required. The ease of production, weight of the final product, and exceptional resilience of aluminum cast lighting are the main reasons for its popularity.

Agricultural Equipment

Many of the aluminum cast parts for agriculture have similar requirements and specifications to those produced for the auto industry. The difference is the increased strength and lasting stability required by agricultural machinery due to the harsh conditions and constant use. An additional factor is cost, which is a major concern for agricultural production. It is for these reasons that aluminum castings are used for crankcase housings, gearbox housings, and motor housings.

Aluminum electric motor housing

Heatsinks

The function of a heatsink is to remove heat parts and components designed for electronic applications. Aluminum cast heatsinks require less machining, which lowers production costs and increases the speed of manufacturing. The extra features of a heatsink, such as cooling fins, are produced at the same time further improving production efficiency.

Die cast aluminum heat sinks

Aluminum cast heatsinks are electrically conductive, which means they can be grounded. They are cast with additional features included to eliminate secondary operations such as machining and assembly to reduce costs.

Brackets

A common use for the aluminum casting process is the manufacturing of brackets for heavy duty equipment for industrial use and appliances for home use. The choice of aluminum casting is the near net shape of the final bracket, which eliminates the need for welding or assembly. The single piece construction of aluminum brackets ensures that the bracket will be stronger and less likely to fail. When holes are necessary, they are included in the casting mold to avoid the need for finishing.

Cast aluminum handrail bracket

Golf Products

The durability, stability, and the ability to produce variable shapes is the reason that manufacturers have turned to aluminum casting for the production of golf equipment. The goal of producers is to assist players improve their game with higher quality equipment at a lower cost. The types of golf products include golf ball warmers, golf clubs, handles, and brackets.

Cast aluminum golf ball warmer

Enclosures

Aluminum cast enclosures are designed for housing sensitive electronics in any type of environment. An advantage of using aluminum for an enclosure is its natural level of shielding against radio frequency interference (RFI) and electromagnetic interference (EMI). The seamless construction provided by aluminum casting creates a watertight sealed enclosure capable of withstanding any type of conditions.

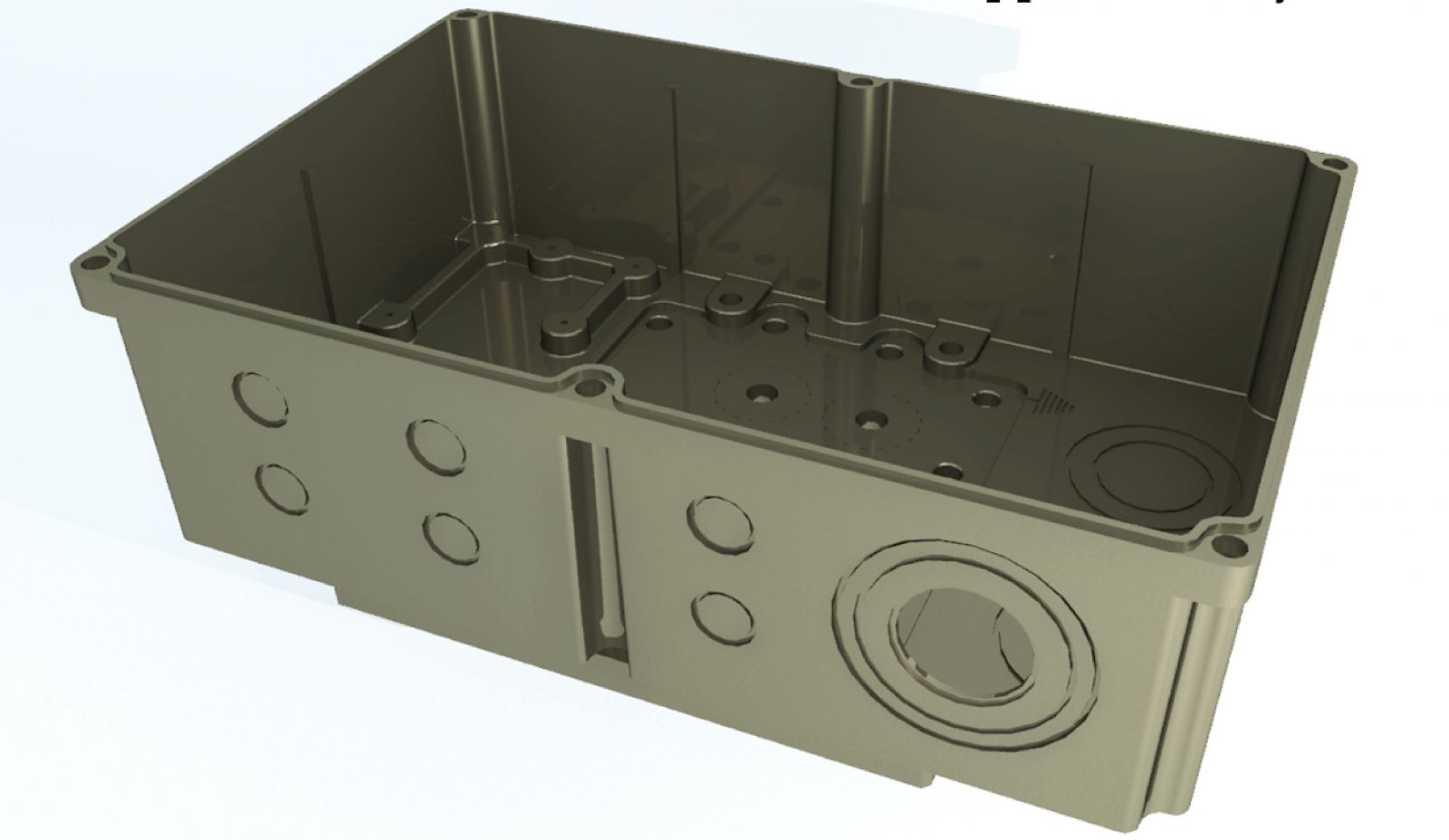

Die cast aluminum enclosure

The requirements for cast aluminum enclosures have been established by the National Electrical Manufacturers Association (NEMA), which provides the standards and specifications that producers must meet to market their products.

Military

There are any number of parts and components produced for the military using aluminum casting, which are required to meet specific government requirements. The production and processing of military parts is outlined in detail that includes the characteristics and properties of the materials. The specialized nature of military components offers a challenge to producers since all military parts require precision engineering and close attention to details.

Die cast aluminum amored vehicle fire suppression system housing

Two unique military components are described below.

- Fire Suppression Housing: The purpose of a fire suppression housing is to suppress fires in armored vehicles such that the vehicle can take a direct hit without endangering the occupants.

- Missile Nose Piece: A missile nose piece is attached to the nose of a missile and is required to be precisely cast in order to withstand the G forces a missile launch produces. The casting process

*Source: iqsdirectory.com

*Image source: Internet

Chia sẻ:

Chia sẻ:.JPG)