Complex Aluminium Extrusions for Automotive Structures

The role of aluminum as a primary material choice for automotive components continues to rise due to the benefits associated with light weight, high strength, energy absorption and recyclability. Manufactures continues to put research and development at the forefront of our ambitions for a safer and more sustainable automotive industry through our latest range of alloys and production capabilities for side sills, sill members and battery tray sills.

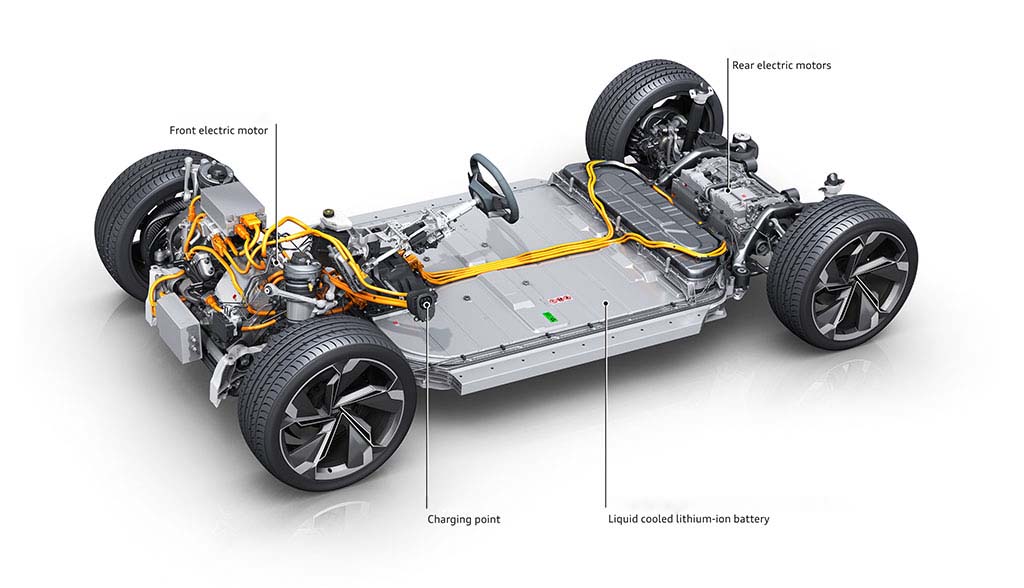

Aluminum battery housing for Electric car

We offer bespoke aluminum extruded profiles our network of automotive extrusion presses, using our catalogue of alloys. This enables us to provide you with complex profiles that take advantage of aluminum's weight-to-strength ratio and high energy absorption properties.

Our production offerings can also provide value-added services. These include CNC machining, welding, punching, stamping, cutting and assembly to develop an extruded profile into a fabricated automotive component with full traceability and reliability through the production chain.

High-strength aluminum alloys for automotive applications

Die-casting engine for Electric car

High-strength aluminum alloys are being specified for structural applications that have elevated strength requirements, like bumper systems, longitudinals and side sills.

We are consistently developing new 6000-series alloys through careful microstructure design and process control to help achieve OEMs’ targets and categories for yield and tensile strength.

Through research and development, we are giving carmakers the ability to choose the aluminum alloys that are optimized for the solution required, the application and its function.

Aluminum for a more sustainable automotive industry

Aluminum is the most sustainable choice for automotive body sheet because it is infinitely recyclable without a loss in its qualities, including lightness, durability, and formability.

Recycling aluminum uses only about 5 percent of the energy to produce primary metal and reduces carbon emissions by as much as 95 percent.

Recycling aluminum scrap in a closed-loop process is an immediate opportunity for vehicle manufacturers to reduce their carbon emissions, while end-of-life recycling offers an opportunity for the future.

Why choose aluminum for your automotive component?

|

Source: https://www.hydro.com/

Chia sẻ:

Chia sẻ: