Aircraft & Aerospace

Take-Away Facts

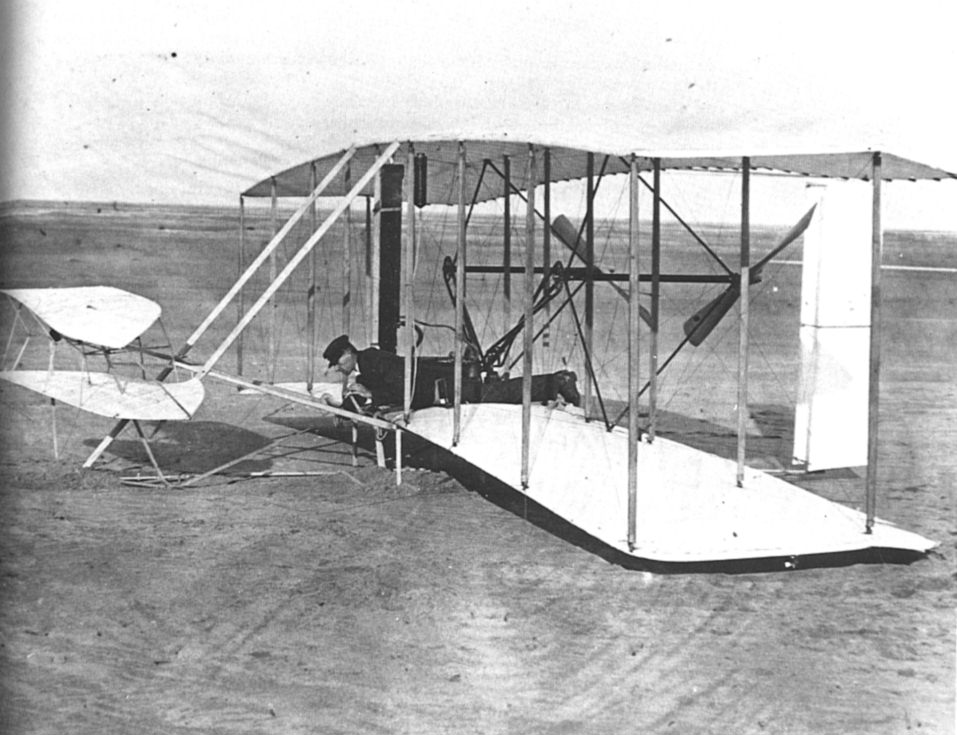

- In 1903, the Wright brothers used aluminum to make the engine crankcase for their first wood-frame biplane.

- In 1942, WOR-NYC broadcast the radio show “Aluminum for Defense” to encourage Americans to contribute scrap aluminum to the war effort.

- The Apollo Command Model was made of an aluminum honeycomb-sandwich bonded between sheets of aluminum alloy.

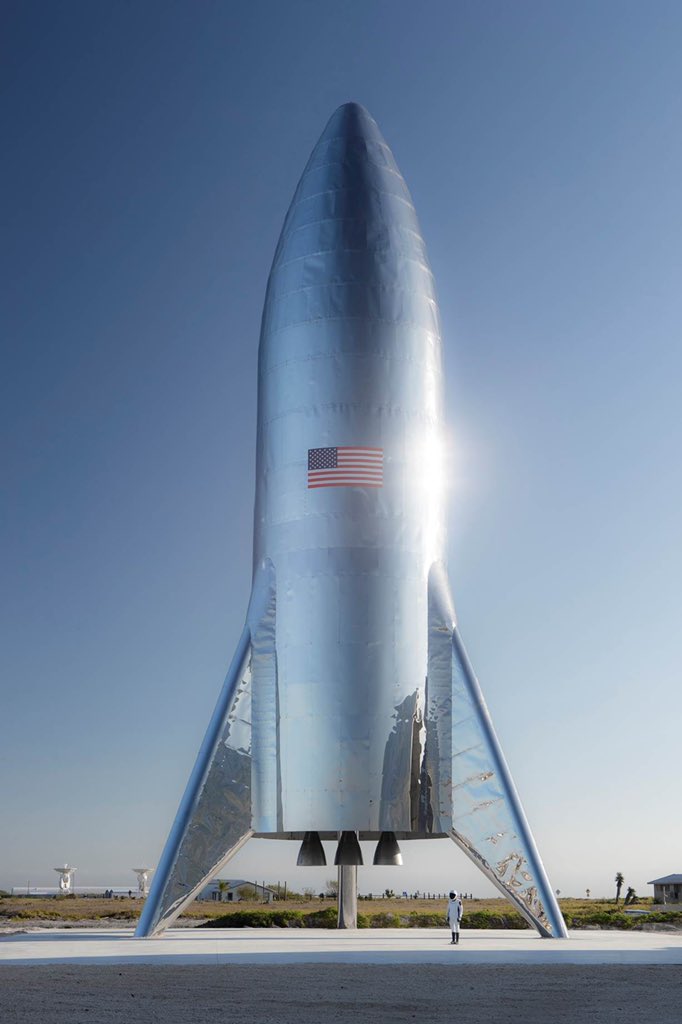

- Lockheed Martin has chosen an aluminum-lithium alloy for the primary structures of NASA’s new Orion spacecraft.

- Aluminum was used as the primary propellant for the space shuttle’s solid rocket booster motor because it has a high volumetric energy density and is difficult to ignite accidentally.

The Wright brothers's first wood-frame biplane

Aircraft

The airframe of a typical modern commercial transport aircraft is 80 percent aluminum by weight. Aluminum alloys are the overwhelming choice for the fuselage, wing, and supporting structures of commercial airliners and military cargo/transport aircraft. Structural components of current United States Navy aircraft are made of fabricated wrought aluminum (forged, machined and assembled parts). Attention is now focused toward aluminum casting technology, which offers lower manufacturing costs, the ability to form complex shapes and the flexibility to incorporate innovative design concepts.

Space flight

Ever since the launch of Sputnik a half-century ago, aluminum has been the material of choice for space structures of all types. Chosen for its light weight and its ability to withstand the stresses that occur during launch and operation in space, aluminum has been used on Apollo spacecraft, the Skylab, the space shuttles and the International Space Station. Aluminum alloys consistently exceed other metals in such areas as mechanical stability, dampening, thermal management and reduced weight.

Apollo spacecraft (Saturn V)

Looking forward: continued space exploration

NASA’s Orion MPCV (Multi-Purpose Crew Vehicle) will serve as the next-generation space exploration vehicle. The primary structures of the Orion spacecraft are made an aluminum-lithium alloy and will be covered by an advanced version of the thermal protection tiles used on the space shuttle.

NASA’s Orion MPCV

The History of Aluminum in Aerospace

The first person to understand the potential of aluminum in the aerospace industry was the writer Jules Verne. His novel Journey to the Moon (published in 1865) provided a detailed description of an aluminum rocket. In 1903, the Wright brothers built their wood-framed biplane with an aluminum crankcase engine. In World War I, lightweight aluminum became essential in aircraft design and development. During WWII, the production of aluminum soared. U.S. aircraft production (July 1940-August 1945) totaled an astounding 296,000 aircraft. More than half were made primarily aluminum. From there, alloys were used to construct early rockets. The body casing of the Avantgarde and Titan rockets used for launching the first American rockets into orbit were made of aluminum alloys.

Source: https://www.aluminum.org/product-markets/aircraft-aerospace

Images source: Internet

Chia sẻ:

Chia sẻ: