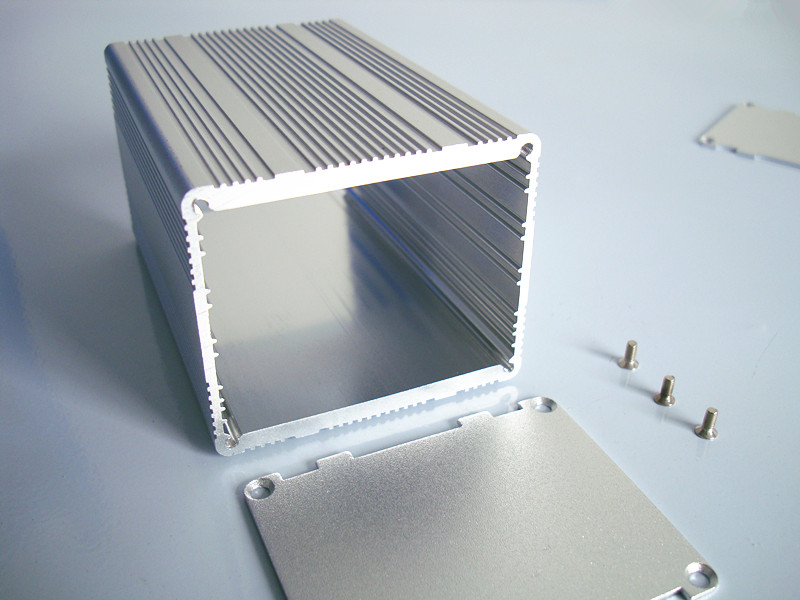

10 Exceptional Benefits of Aluminum Enclosures

Why select an aluminum enclosures over a case made of other materials such as plastic or composite? The 10 exceptional benefits of aluminum – listed below – will help you decide.

1. Very Light Weight

Aluminum has a high strength-to-weight ratio. Aluminum enclosures are lightweight, yet strong.

2. Extremely Strong

The strength of aluminum offers much better fracture toughness than most other materials used in enclosures construction. It is resistant to impacts, mechanical breakage, and propagation of fractures; it does not easily stress, tear, or crack.

3. Extraordinary Resistance to Corrosion

Aluminum is highly resistant to nearly all substances – such as salt water – that cause corrosion and weathering. Exposure to UV rays for long periods has no effect.

4. Insensitive to Temperature Extremes

The characteristics of aluminum remain constant over a wide temperature range – 80 °C to + 150 °C. In cold weather, aluminum enclosures do not become more fragile and brittle; instead, the tensile strength increases without lose of ductility. The low coefficient of thermal expansion of aluminum allows it to sustain higher temperatures without distortion.

5. Naturally Protects Electronics

Aluminum has the highest electrical conductivity-to-weight ratio of any metal. An aluminum enclosures is excellent for RFI / EMI shielding and controlling ESD (electrostatic discharge). Aluminum is also an efficient reflector for externally generated interference, namely, electromagnetic wavelengths of radio and radar.

6. Excellent Heat Dissipation

Aluminum is widely used in heat sinks and heat exchangers because of its high thermal conductivity. In a shipping case, it efficiently transports heat away electronics and other equipment. Aluminum has high reflectance to encroaching radiated heat such as sunlight (aluminum has a light reflectivity over 80%).

7. Suited for Harsh Environments

For rugged and outdoor environments, aluminum enclosures can be fitted with options to meet watertight, splash-proof, drip-proof, and salt spray requirements. Water vapor will not diffuse through aluminum or through a welded seam.

8. Low Cost Customization

Aluminum enclosures can be easily customized using secondary operations such as drilling, laser cutting, riveting, welding, brazing, soldering and more. There’s no need to pay for a special mold. Aluminum is often easier to modify than cases of other materials.

9. Beautiful Finishes

Aluminum enclosures accommodate virtually every kind of finish whether mechanical (such as brushing or polishing) or chemical (such as anodizing). Almost any coating, such as paint and powder coatings, can be applied.

10. Aluminum is Safe

Aluminum is non-toxic, odorless, tasteless, non-absorbing, non-sparking, non-magnetic, and non-flammable. Therefore, aluminum enclosures can be used in a wide variety of special environments, such as sanitary and clean rooms, food service areas, and in many volatile applications. It is also fully recyclable.

Source: Polycase.com & Sierracases.com

Images source: Internet

Chia sẻ:

Chia sẻ: