Capacity Of Kimsen

Extrusion

Extrusion

Currently, KIMSEN is operating 3 modern technology aluminum extrusion lines of 920 UST, 1100 UST & 1880 UST, which are able to produce approximately 800 tons/month.

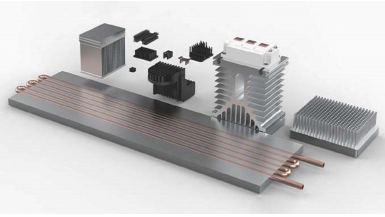

Die Casting

Die Casting

KIMSEN has a diversified range of products which are being used in a broad range of fields and applications such as Mechanical & Electrical, Transportation, Construction, Furniture, Automotive, Energy, etc.

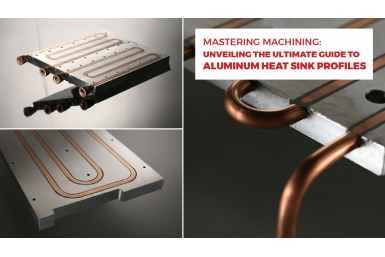

Surface Treatment

Surface Treatment

KIMSEN has installed anode coating lines including Natural, sandblasting, ED coating, hard anodizing, nickel plating, electric nickel plating, tin plating, liquid coating, and E-coating lines are gradually gaining market recognition.

SustainabilityDevelopment

Environmental pollution and climate change are always problematic and require the persistent effort of every nation, every organization and every individual.

See more